15.04.2024 | Company magazine

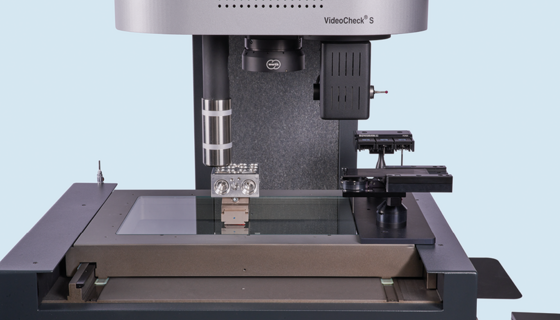

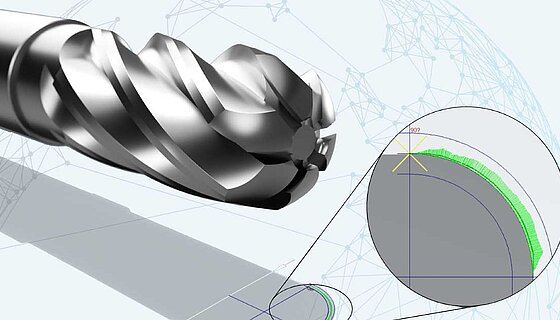

10.04.2024 | Economical measurement with multi-sensor systems

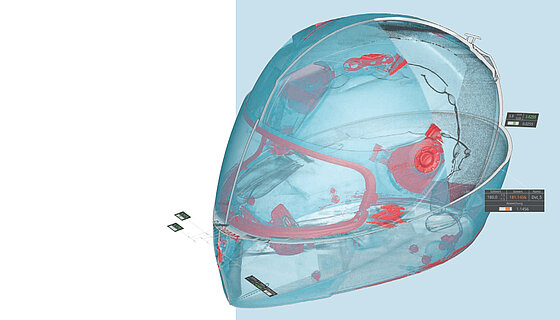

18.03.2024 | News on multi-sensor systems and computed tomography

03.03.2024 | Economical measurement with computed tomography

13.02.2024 | Economic measurement with multi-sensor systems

29.01.2024 | Economical measurement with multi-sensor systems

16.01.2024 | Economical measurement with computed tomography

11.12.2023 | News about the Werth Group

30.11.2023 | Economical measurement with computed tomography

26.11.2023 | Economic measurement with multi-sensor systems

31.10.2023 | Economic measurement with multi-sensor systems

24.10.2023 | Economic measurement with computed tomography

25.09.2023 | Economic measurement with multi-sensor systems

04.09.2023 | News on computed tomography

31.08.2023 | News on multi-sensor systems

14.08.2023 | News on computed tomography

31.07.2023 | News on multi-sensor systems

13.07.2023 | News on computed tomography

10.07.2023 | News on multi-sensor systems

04.07.2023 | News on computed tomography

03.07.2023 | News on multi-sensor systems

22.05.2023 | Company magazine

07.05.2023 | News about the Werth Group

13.03.2023 | News about the Werth Group

28.02.2023 | News about the Werth Group

13.02.2023 | News on computed tomography

31.01.2023 | News about the Werth Group

17.01.2023 | News about the Werth Group

03.01.2023 | News on computed tomography

07.12.2022 | News on multi-sensor systems

01.12.2022 | News on multi-sensor systems

30.11.2022 | Werth technical articles

17.11.2022 | News on computed tomography

14.11.2022 | News on computed tomography

06.11.2022 | News on multisenorics

18.10.2022 | News on multisenorics

05.10.2022 | News on computed tomography

19.09.2022 | Werth user report

31.08.2022 | News on computed tomography

15.08.2022 | News on multi-sensor systems

01.08.2022 | News on computed tomography

19.07.2022 | News on computed tomography

18.07.2022 | News from multisenorics