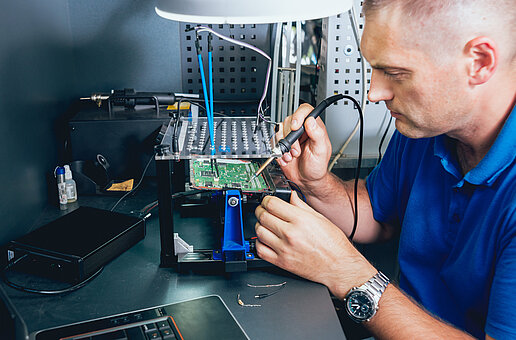

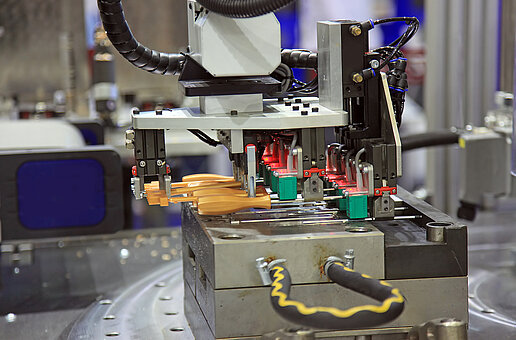

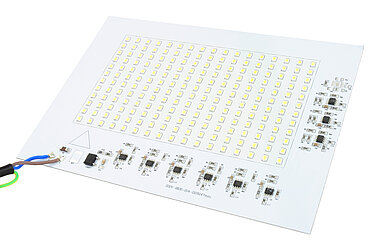

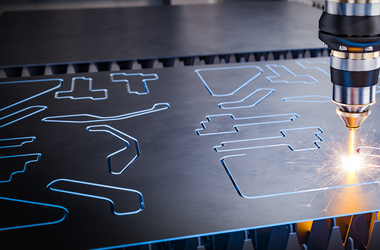

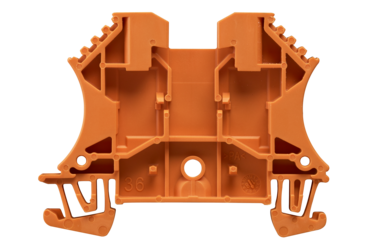

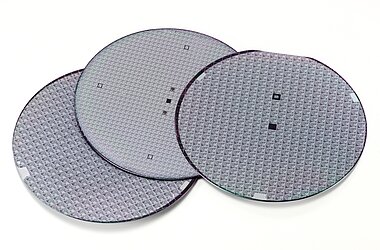

Short product cycles and high quantities place special demands on manufacturers of electronic components. Many everyday items contain printed circuit boards and microprocessors. The demands on geometry are high, as assembly is usually automated.

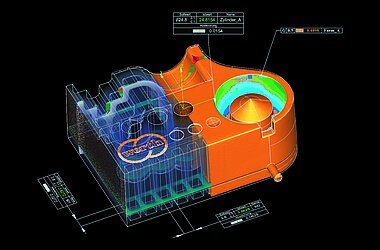

Werth multisensor coordinate measuring machines are used to measure the small, sensitive electronic components, usually without contact, for example wafers in pre-production, workpiece positioning of automatic placement machines or the coplanarity of solder points on integrated circuits (ICs).

The industry association SEMI (Semiconductor Equipment and Materials International) issues international safety standards for the use of coordinate measuring machines in the semiconductor industry. The guidelines of the SEMI organization are becoming increasingly important worldwide and must be evaluated by an independent third party. Certification by TÜV (Technischer Überwachungsverein) is possible for Werth coordinate measuring machines.