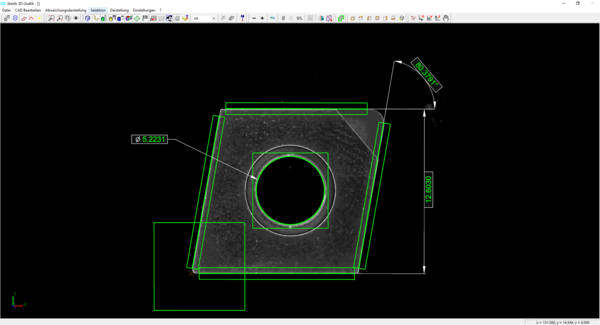

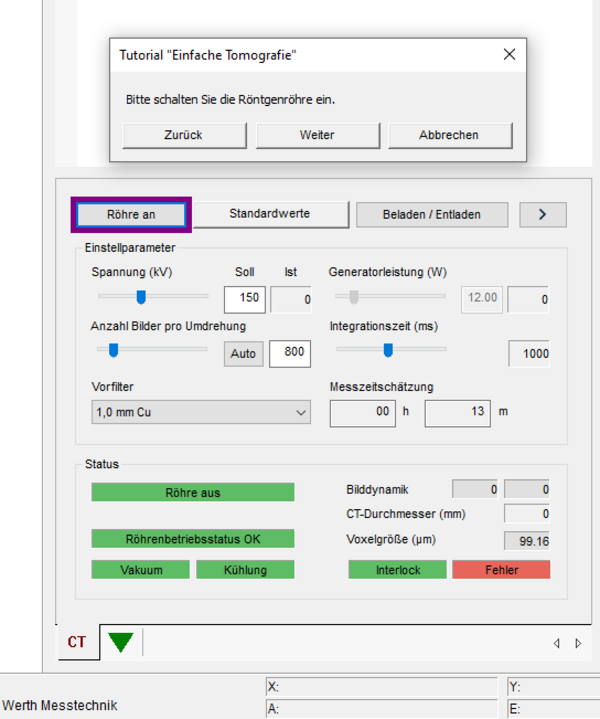

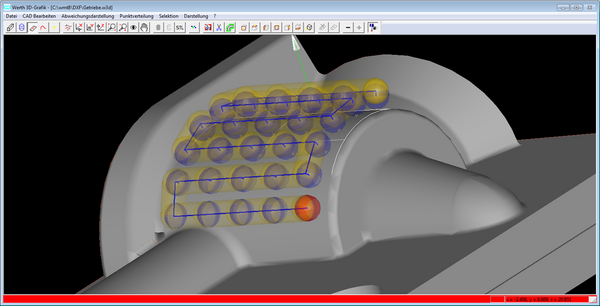

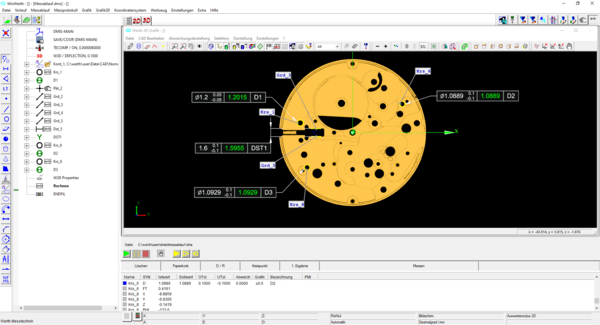

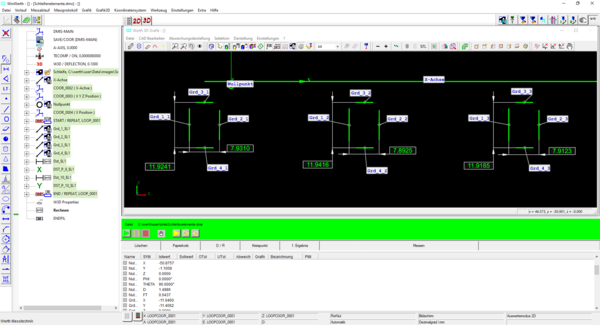

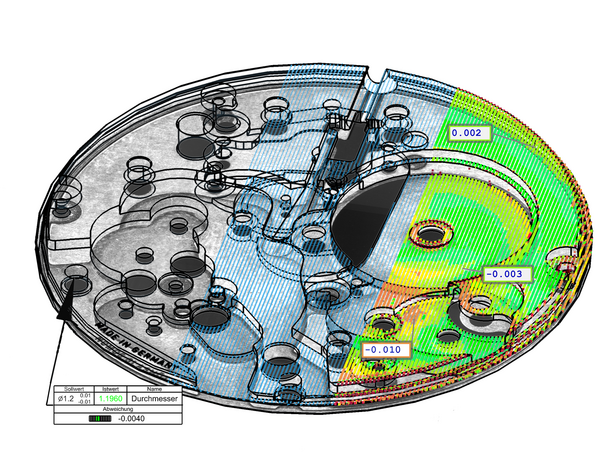

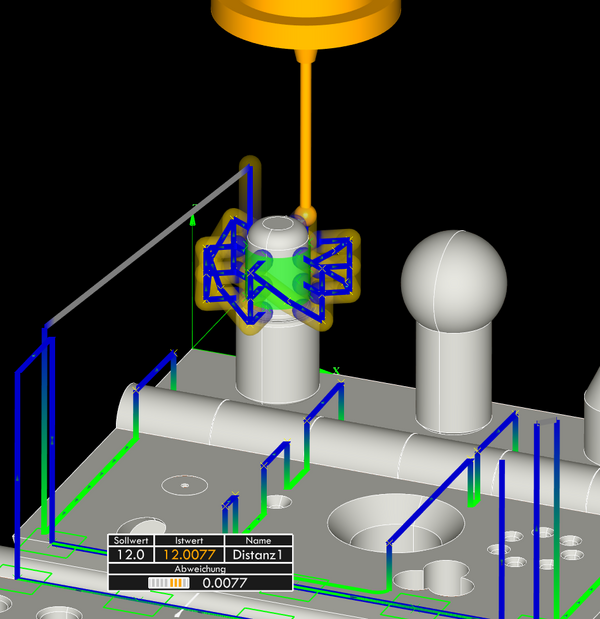

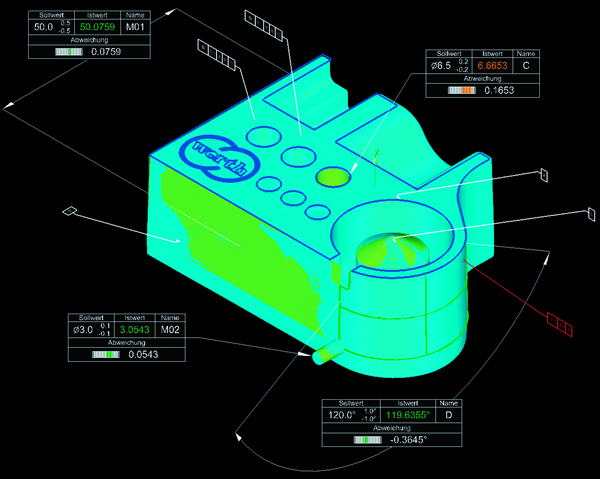

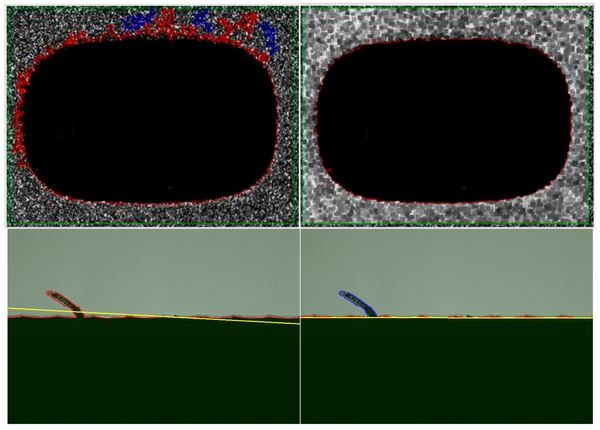

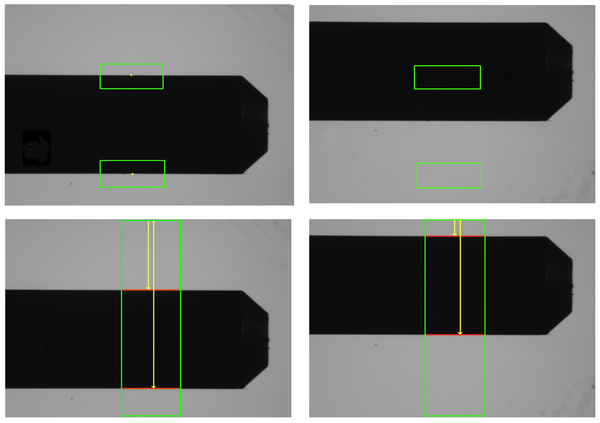

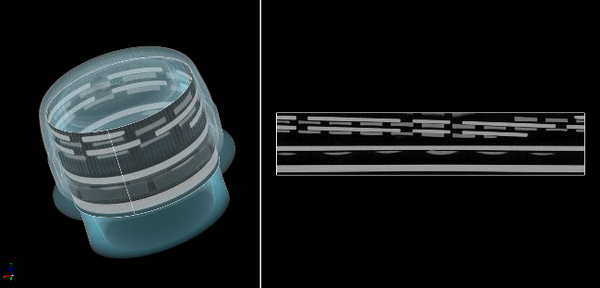

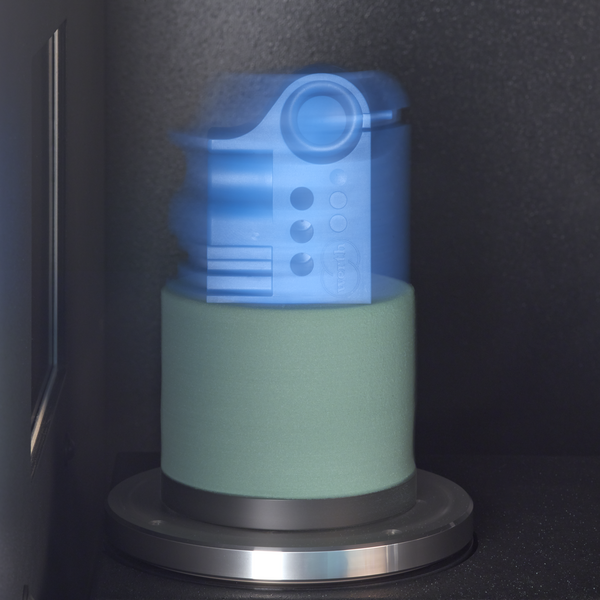

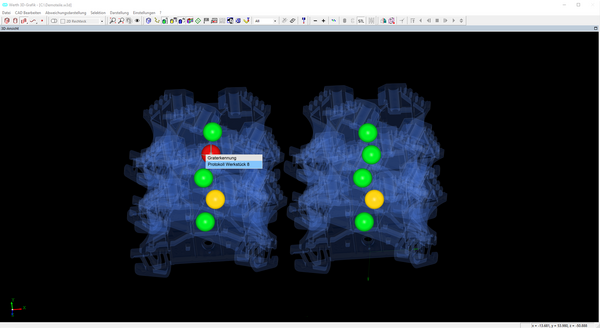

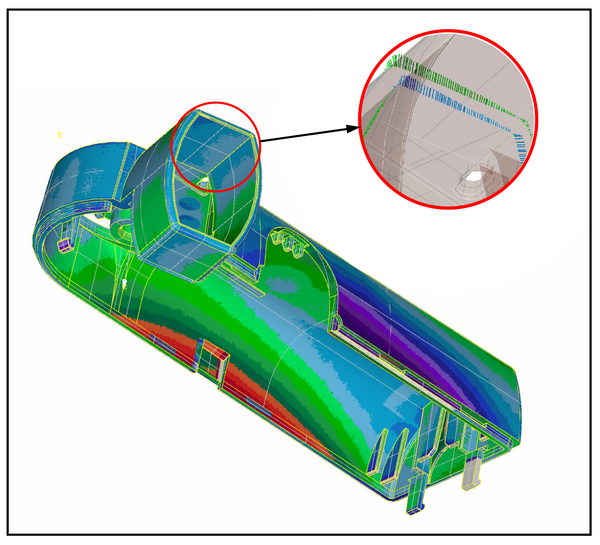

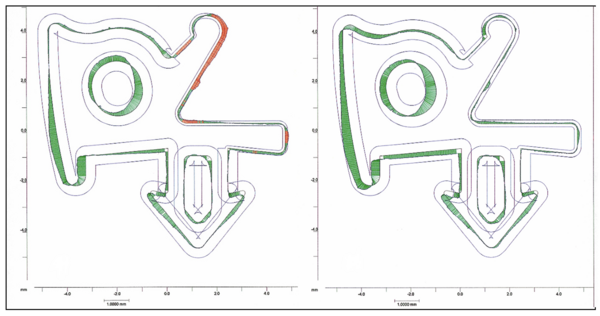

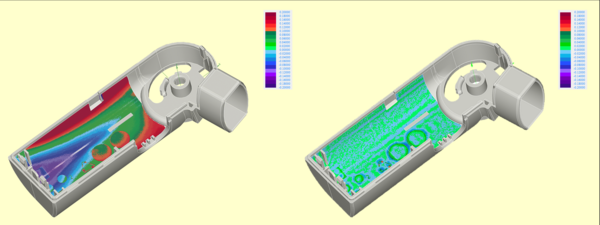

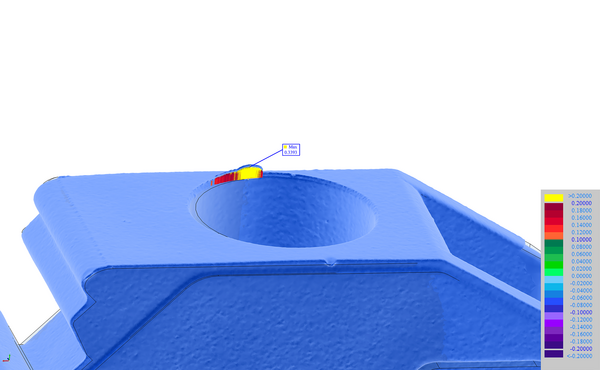

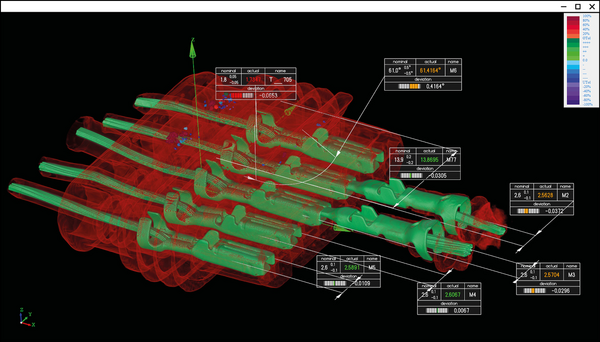

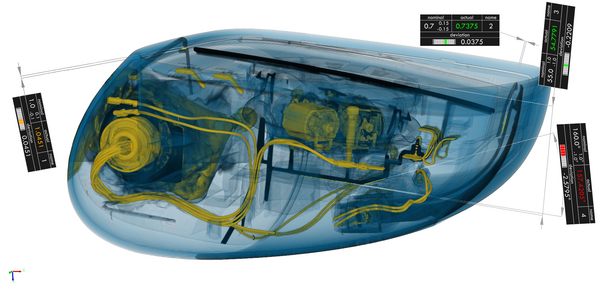

The operation of machines with a wide variety of sensors, as well as the evaluation of volume data and point clouds, are possible with WinWerth® in a unique combination. The Werth image processing software is based on 40 years of experience and is the basis of what is probably currently the most powerful image processing sensors for coordinate measuring machines. Optical distance sensors, conventional probes in single-point or scanning mode, the Werth Probe®, X-ray computed tomography or machines with a combination of several sensors are all supported by the uniform concept. Measurement points, 2D images or volume data can also be conveniently evaluated in terms of geometrical characteristics or with nominal-actual comparison. PTB-certified evaluation algorithms ensure correct measurement results. All desired information is displayed in the graphics: CAD models with PMI data, voxel volumes, measurement point clouds, color-coded deviation plots from 3D nominal-to-actual comparisons, video images, measurement and calculation elements as well as flags with nominal and actual values, tolerances and deviations. The software has a modular structure to meet a wide range of requirements. Various devices can be operated, from simple measuring projectors to complex multi-axis coordinate measuring machines with multi-sensor technology or X-ray tomography sensors.

Modern coordinate measuring machines cover a wide range of tasks of varying complexity. The qualifications of the machine operators range from employees with little training, who only occasionally determine a few sizes, to specialists who, utilizing all technically feasible options, also perform very difficult measuring tasks. The very different working methods are optimally supported by the structure of the WinWerth® software for device operation. For example, there are several access levels at , which are tailored to the different qualification levels of the operators. Interfaces to CAD systems for importing nominal data and to CAQ systems for statistical evaluation enable the coordinate measuring machines to be integrated into company software structures.