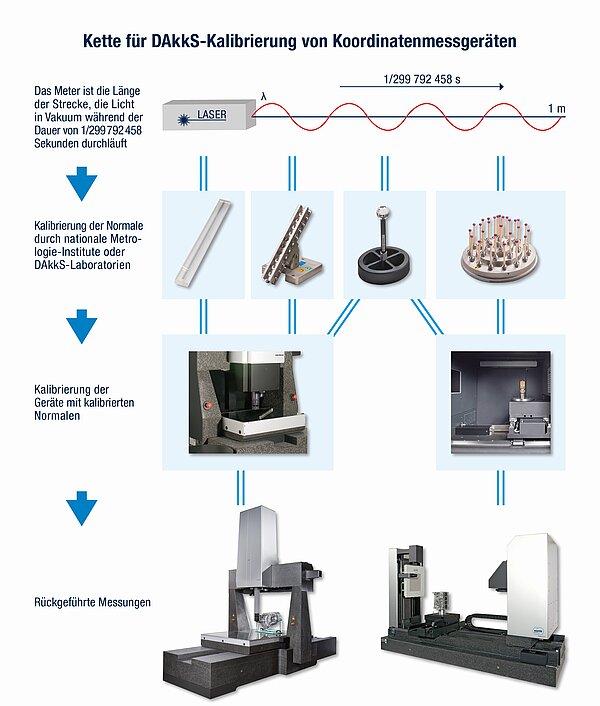

Specifications according to uniform standards and certified calibration enable an objective comparison of the performance of measuring machines and ensure traceability of measurements. Werth Messtechnik was accredited for the calibration of optical and multisensor coordinate measuring machines back in 2004, and in 2011 it became the first and, until 2018, only facility of its kind to be accredited for the calibration of coordinate measuring machines with computed tomography sensor systems.

-

Applications

- 3D free-form workpieces

- Extruded workpieces

- Molds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Punched and bent parts

- Packaging

- Shaft-Hub Connections

- Shafts and Axes

- Workpieces with micro-features

- Optics and Lenses

- Tools with precisely defined cutting edges

- Tools with complex or irregular cutting edges

- Gear wheels

- Cylindrical workpieces

- Industries

- Our products

- Werth service

- About Werth

- Careers

- Foundation

- Publications

- Downloads