Schwanog relies on state-of-the-art automation to combine cost-effectiveness and the highest quality in the production of inserts. Thanks to the close networking of automation and grinding technology from Adelbert Haas GmbH and robust and accurate measuring machines from Werth Messtechnik GmbH in automated production cells, the company is able to make its production processes not only more economical, but also more reliable – around the clock.

Schwanog, headquartered in Villingen-Schwenningen, was founded back in 1946. Today, with its self-developed grooving tools and tool changing systems, the company is one of the leading international manufacturers of profile tools in this market segment. Application-specific tools are also produced in small batch sizes at several production sites around the world.

Sanding process of a profile plate

Fully automated process – from order to dispatch

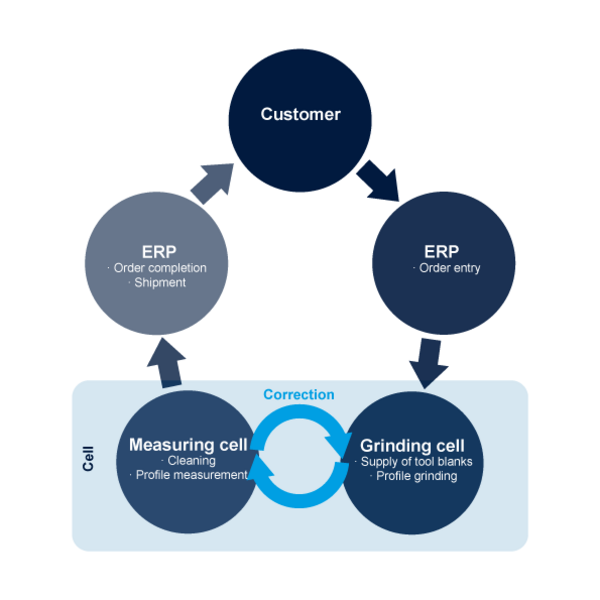

In industrial tool production, it is not only precision that counts, but also the reliable quality of each individual workpiece. At the same time, many companies are faced with the challenge of making their production efficient and economical despite a shortage of skilled workers – Traditional shift models are increasingly reaching their limits. Schwanog meets these challenges with fully automated production cells. The entire production and testing process, from ordering to shipping, runs out within a cell without any human intervention – a 'factory within a factory'.

View of the measuring cell with ScopeCheck® S and robot

In the production cell, a robot feeds the grinding machine with tool blanks. A large parts warehouse enables a great variety in production without retooling. According to the grinding process, the first insert is cleaned and measured. If the profile is within the required tolerances, series production starts. If not, the grinding process is corrected fully automatically – Usually, a single iteration is enough to grind a perfect profile. This closed-loop process achieves maximum accuracy and cost-effectiveness from a batch size of just one. The inspected panels are then automatically packed and dispatched. At the same time, the system documents all relevant data – including a test report of each panel for the customer. "Thanks to the closed-loop process, we ensure consistently high production quality – and do so completely autonomously," says Clemens Güntert, President of Schwanog Siegfried Güntert GmbH. "Fully automated production enables us to make optimum use of our resources and significantly increase productivity."