What are you doing, Mr. Mandler?

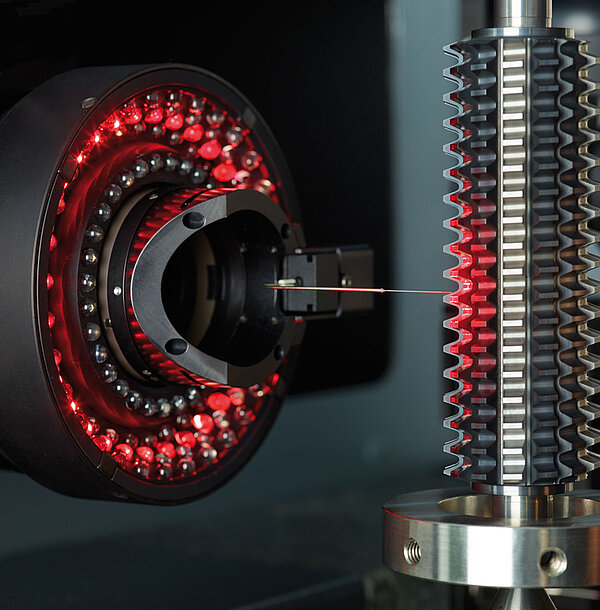

I produce the fibers for our patented Werth Fiber Probe® micro-probe. To do this, I enter the desired parameters in the software, such as the probe ball diameter, shaft length and shaft diameter. Then I roughly cut the glass fibers to the right length and clamp them in the specially developed fiber drawing stand. There, electrodes are used to generate a plasma in which the fiber is heated and drawn into the preset geometry.

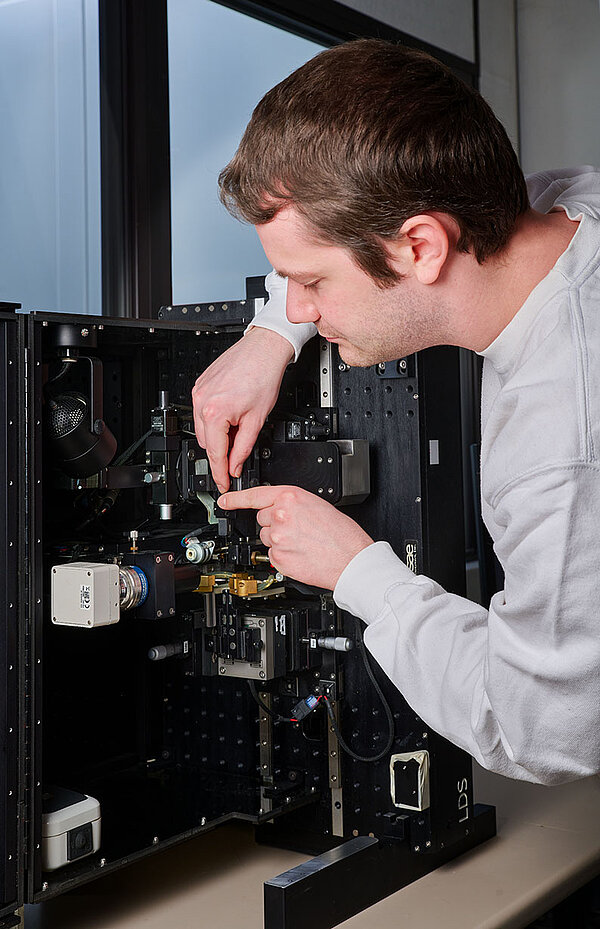

Frederik Mandler produces the fibers for the patented Werth Fiber Probe® microprobe

What is your background?

My father introduced me to Werth Messtechnik back then. I first completed a one-year internship in assembly for my vocational baccalaureate. I then started an apprenticeship as an industrial mechanic in 2014. According to my apprenticeship, I was taken on and employed in bridge-type machine assembly. When my predecessor in fiber production retired, I was given the opportunity to take over his work.