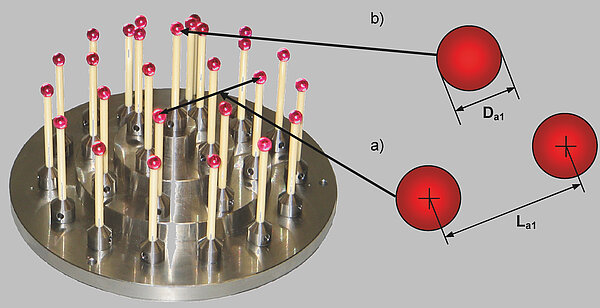

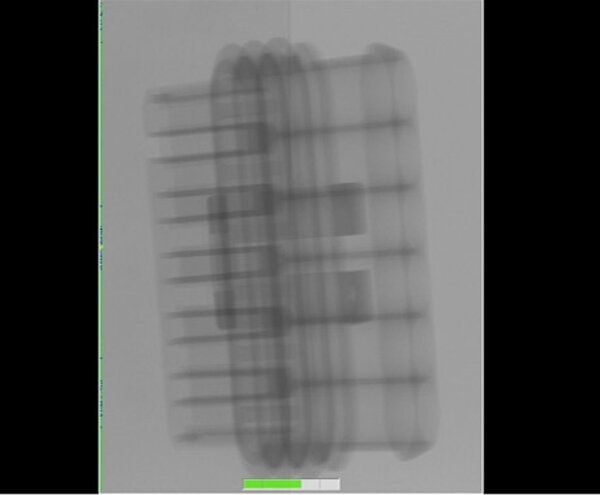

In addition to the highest demands on the device components, new procedures for qualifying the TomoScope® device geometry have been developed. The use of traceable calibration standards ensures the traceability of measurements on real workpieces.

-

Applications

- 3D free-form workpieces

- Extruded workpieces

- Molds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Punched and bent parts

- Packaging

- Shaft-Hub Connections

- Shafts and Axes

- Workpieces with micro-features

- Optics and Lenses

- Tools with precisely defined cutting edges

- Tools with complex or irregular cutting edges

- Gear wheels

- Cylindrical workpieces

- Industries

- Our products

- Werth service

- About Werth

- Careers

- Foundation

- Publications

- Downloads