WinWerth® version 9.44 includes many new functions for Werth ScopeCheck®, VideoCheck® and TomoScope® machines, as well as improved ease of use, speed and flexibility. One example is the extension of the PMI functions. According to the selection of the geometrical characteristic, for example a position deviation, all required geometrical elements are measured with automatic point distribution. The measured value is output including the deviation from the target value taken from the CAD model.

Both the TomoScope® machines and the multi-sensor systems allow ever shorter measuring times. To enable real-time evaluation even with large amounts of data, functions for parallel evaluation of measured data with several computers have been integrated into WinWerth®. As soon as the run-out evaluation is finished, the now free PC automatically picks up the next task. This also makes it possible to organize a complete measurement including evaluation in unmanned shifts overnight or at the weekend.

The deviations from various local target/actual comparisons of the workpiece, even in different alignment states, can now be displayed simultaneously in color-coded form. This new function is suitable for workpieces with several functionally relevant areas whose positions in relation to each other can deviate greatly from the target state.

The new Envelope Scanning following the cutting edge enables even faster measurement of the cutting edge contours of rotationally symmetrical tools. The image processing sensor follows the cutting edge with the help of a synchronized movement of the device axes.

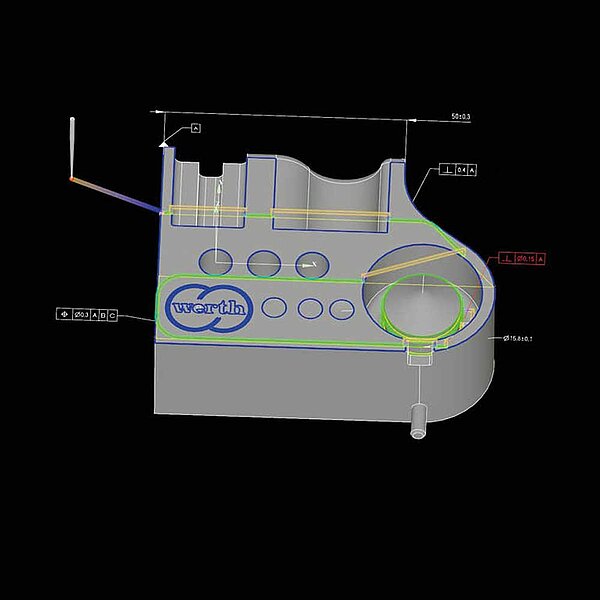

Measurement with PMI data: According to the selection of perpendicularity (red), scan paths (green) are automatically distributed to the cylinder and reference plane for the predefined sensor