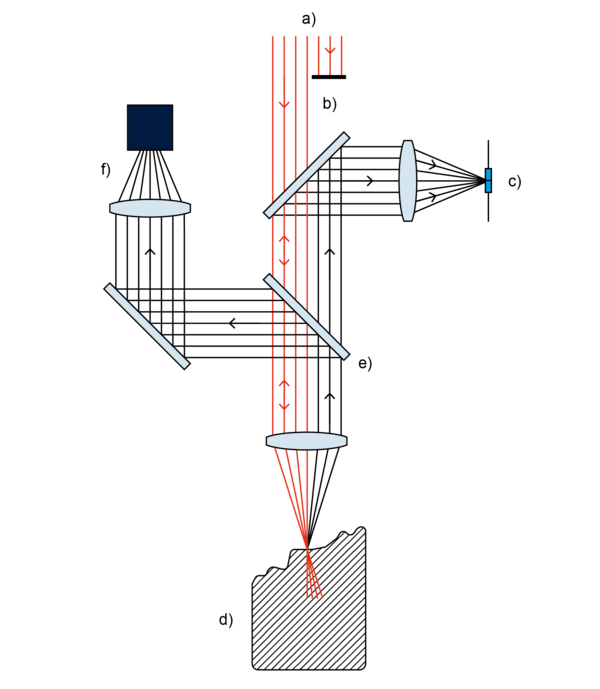

In order to be able to carry out three-dimensional (3D) measurements of workpieces with optical sensors, a method for measurements along the third coordinate axis is required in addition to the image processing sensor. One such distance sensor is the Werth Laser Probe (WLP), which can be integrated into the beam path of the Werth Zoom to combine edge and distance measurements without mechanical sensor change (patent).

-

Applications

- 3D free-form workpieces

- Extruded workpieces

- Molds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Punched and bent parts

- Packaging

- Shaft-Hub Connections

- Shafts and Axes

- Workpieces with micro-features

- Optics and Lenses

- Tools with precisely defined cutting edges

- Tools with complex or irregular cutting edges

- Gear wheels

- Cylindrical workpieces

- Industries

- Our products

- Werth service

- About Werth

- Careers

- Foundation

- Publications

- Downloads