In helical tomography scans, the measuring object is moved helically along the rotary axis as it rotates. This has the benefit that all parts of the measuring object are irradiated at least once horizontally from the source to the detector. Due to the principle, no cone beam or ring artifacts occur and the systematic measurement errors are correspondingly lower.

The fast image acquisition by OnTheFly CT (patent pending) and the use of large detectors with small distances between the X-ray source and detector shorten the measurement time. With a large aspect ratio of length to diameter, such as long workpieces or fixtures with several stacked workpieces, the measurement time is less than with Raster Tomography. An additional cone beam artifact correction (patent) is not necessary and this often also reduces the evaluation time.

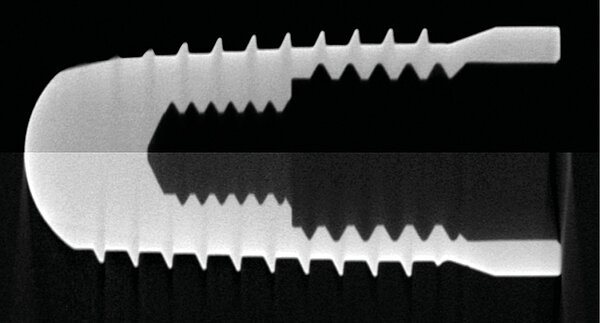

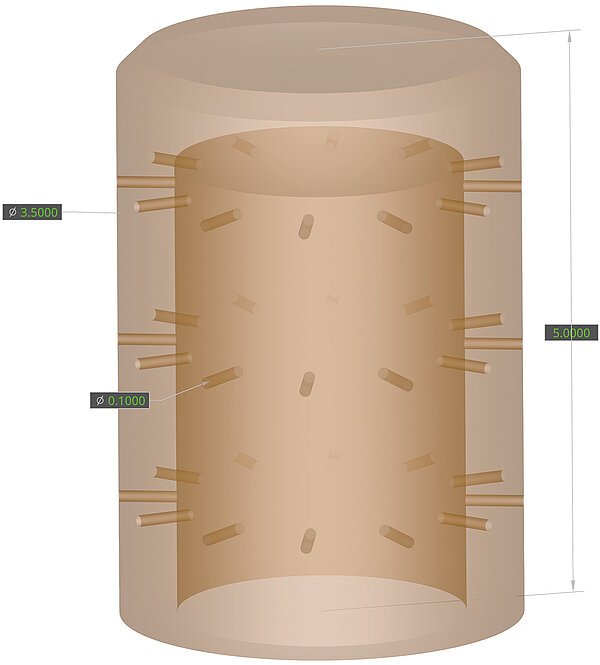

Millimeter-sized endoscope nozzles with injection hole diameters of around 100 µm can be measured in the production cycle using the new computed tomography coordinate measuring systems and measurement methods

With conventional cone beam CT, systematic measurement errors occur as the cone angle increases. With the Werth software correction methods, these measurement errors are reduced to a few micrometers. Due to the horizontal irradiation of all parts of the measuring object, an exact reconstruction is possible with helix CT, so that the cone beam artifacts and the need for corresponding correction methods are eliminated as a matter of principle.

One example of an application for helical tomography is endoscope nozzles. These are millimeter-sized metal workpieces with several dozen injection holes. Spray hole diameters in the two-digit micrometer range require a high resolution and therefore the use of transmission sources. With tolerances in the 10 µm range, measurement errors should not exceed 1 µm to 2 µm. In addition, the use of a transmission source enables high-resolution measurements with high measuring speed, as much smaller focal spots are usually available compared to reflection tubes with the same power.