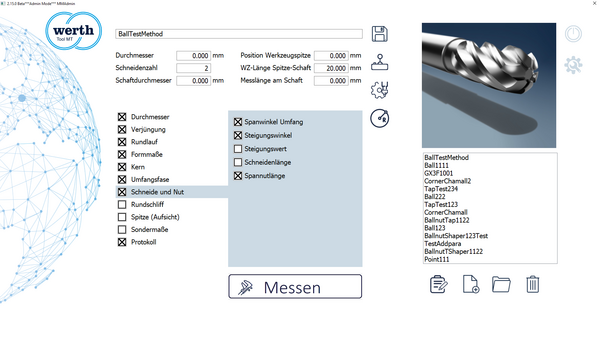

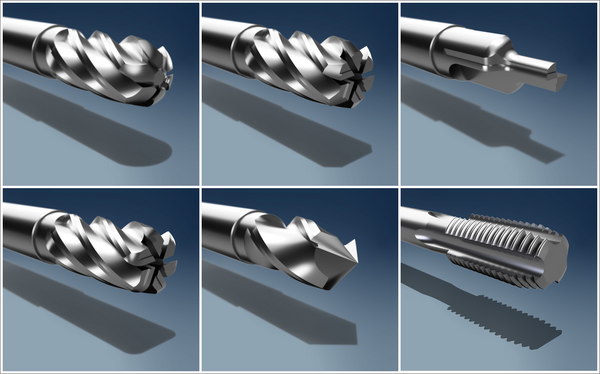

The Werth Precision Tool Pro tool measurement program enables simple tool measurement with proven and standardized measurement sequences on all machines in the ScopeCheck® and VideoCheck® series. The intuitive operation and operator-independent measurement results are just as much a guarantee for successful integration into your quality assurance as the high level of flexibility thanks to the many tool types available for measurement.

A uniform software concept, even across different machine types, and sophisticated user management enable flexible use of our tool measuring machines. The intuitive user guidance supports both the trained metrology technician in the laboratory and the grinder directly in production; it makes no difference whether it is a quick measurement of the outer contour in the Werth Messtechnik or complete tool measurements on machines with four or even five axes. The operation remains the same!

The optimized use of multi-sensor systems with sensors matched to the measuring task in the modular Werth system also offers security for the future thanks to numerous expansion options. The ability to seamlessly connect to existing or planned automation solutions and a wide range of interfaces for data import and export are a matter of course for Werth. For example, the extensive connectivity to SPC and CAQ systems and automation solutions allows automatic correction of the grinding paths in one to two iterations.

With the latest version, you benefit from:

✅ Extended selection of tool types

✅ Automated measurement program creation

✅ Simplified operation

✅ Full connectivity for integration into your quality assurance

✅ Automatic grinding path correction with one to two iterations

Challenge us and contact our experts in the field of tool measurement.