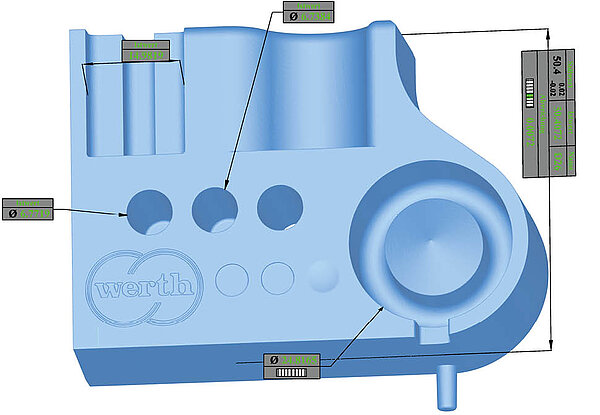

Until now, the teaching of volume-based evaluations was not possible without a real test measurement. TomoSim is the first coordinate measuring software to simulate the tomography process offline using CAD data or a point cloud in STL format. The realistic simulation, taking into account the set CT parameters, enables the calculation of a volume including all significant artifacts. For example, an initial sample inspection program can be taught in at an offline workstation in parallel with the production of the first workpiece and the performance of other measurements on the machine using the WinWerth® measurement software. This enables TomoSim to speed up processes and reduce downtimes, e.g. for TomoScope® machines in multi-shift operation.

In addition to a completed program creation and feasibility check in time for the completion of the first workpiece, the simulation of the tomography process allows the testing and optimization of CT parameters. With the help of the simulated volume, significant artifacts, e.g. due to beam hardening or too few rotary increments, can be detected and, if necessary, an appropriate artifact correction can be selected. Another new feature is the complete offline programming of volume-based evaluations such as burr detection, void analysis, porosity analysis, text recognition, SurfaceScan Predefined or in volume sections.

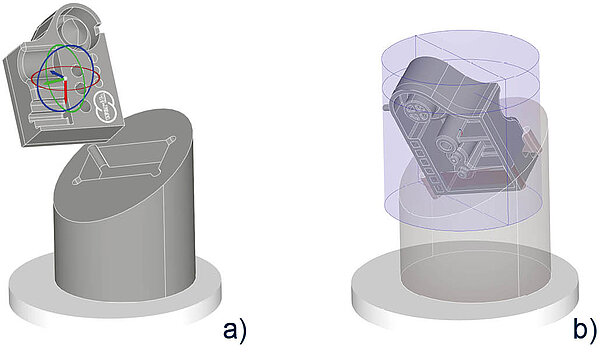

Representation of the rotary table with workpiece holder and workpiece a) and measuring range cylinder calculated by TomoSim for scanning tomographically b)

Simulation based on CAD models or STL point clouds and the workpiece material is also possible for multiple measurements and the simultaneous measurement of different workpieces. Operation is similar to that of a real measuring process. You select the magnification, special measurement methods such as the patented Multi-ROI CT and the CT parameters. According to the start of the simulation, the image stack is simulated and the volume is reconstructed in parallel as in a real measuring process.