Large cone beam angles

Tomography scans with a cone-shaped X-rays enable short measurement times by capturing large areas of the workpiece simultaneously. However, as the cone beam angle increases, the workpiece is scanned more poorly. The resulting cone beam artifacts can be simulated on the target geometry using a patented process and used to correct the measuring volume.

The correction can be calculated by simulation on the CAD model or on a point cloud of a master part measurement of the workpiece. Once calculated, the correction can be applied to point clouds of the same workpiece or other workpieces of the same type, e.g. for a series measurement. Volumes can also be corrected. The correction is calculated on the basis of a simulation on a point cloud of the measured workpiece.

By measuring with a larger cone beam angle, it is possible to reduce the measuring time with the same repeatability or improve the repeatability with the same measuring time. This is achieved by using a larger proportion of the available radiation energy, for example by reducing the focus-detector distance (FDD) at the same imaging scale. The resulting cone beam artifacts and the resulting systematic measurement errors can be greatly reduced by using cone beam artifact correction.

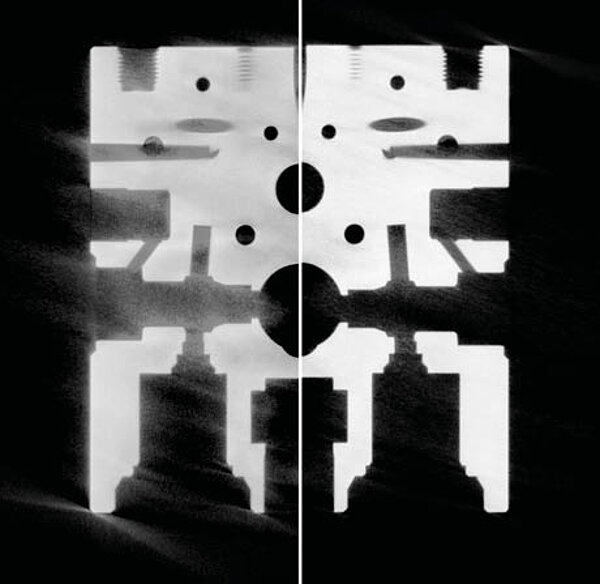

Cone beam artifact correction: volume without (left) and with correction (right)

Ring artifacts in the measurement of low attenuation materials

The sensitivity determines the conversion of X-rays into a measured intensity. Due to differences in sensitivity that are not fully corrected, the same radiation intensity leads to darker or lighter gray values for two adjacent pixels. The back projection of these differences in all rotational positions results in ring-shaped artifacts in the reconstructed volume.

With the new WinWerth® ring artifact correction, the information contained in the intensity images about the sensitivity differences between the pixels is determined from the current measurement and used for fine correction of the images. The ring artifacts are greatly reduced in the reconstructed volume. These are more significant with weakly absorbing workpieces. This correction method is therefore particularly useful for measurements of workpieces with a low attenuation capacity, such as plastic micro-gears, foam material samples or lens packages for smartphones.

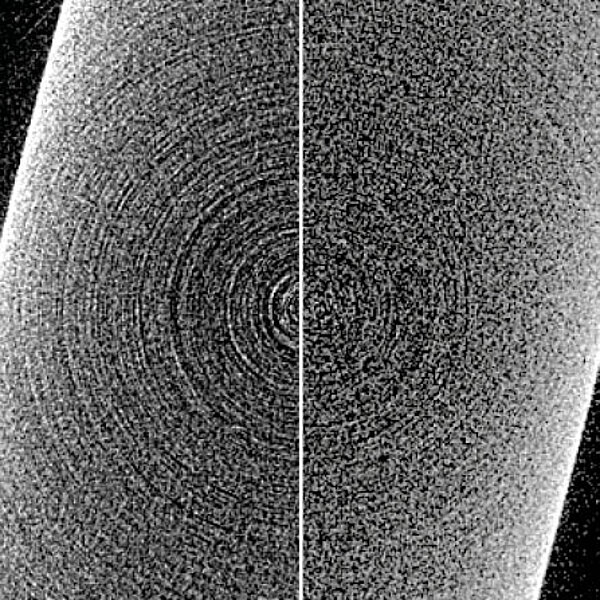

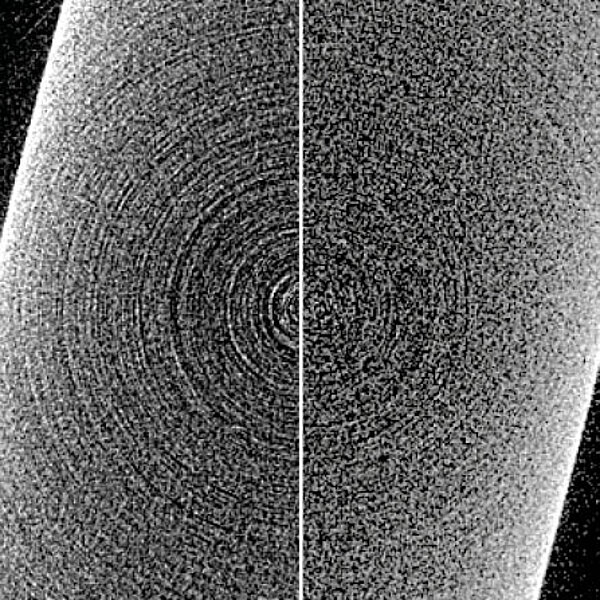

Ring artifact correction: volume without (left) and with correction (right)