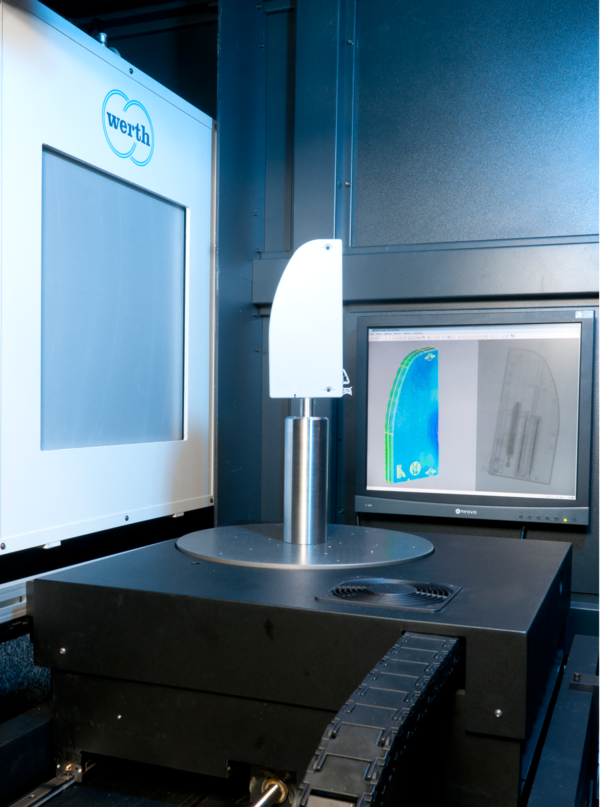

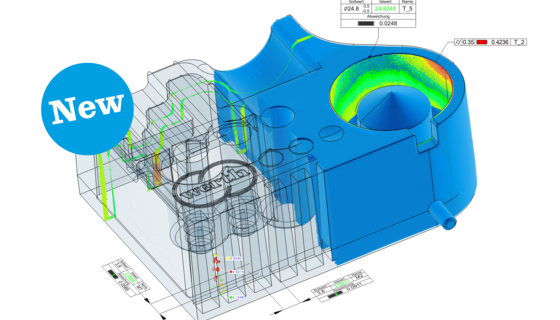

The TomoScope® FQ device family allows up to 50 times faster calculation and evaluation of the measurement point cloud. The geometrical characteristics of workpieces such as valve blocks, housings and castings can be determined almost every half minute, a nominal-to-part deviation analysis can be carried out with the measuring point cloud of a master part and the workpieces can be tested for defects such as burrs. The WinWerth® Scout measurement software offers a clear status display for run-out and completed measuring processes and access to all measurement results at the click of a mouse.

-

Applications

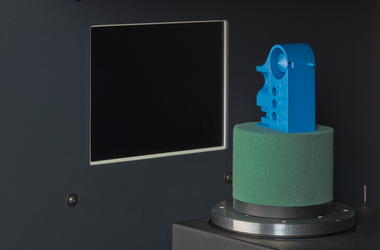

- 3D free-form workpieces

- Extruded workpieces

- Molds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Punched and bent parts

- Packaging

- Shaft-Hub Connections

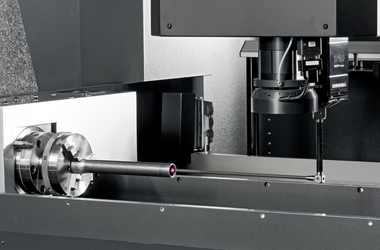

- Shafts and Axes

- Workpieces with micro-features

- Optics and Lenses

- Tools with precisely defined cutting edges

- Tools with complex or irregular cutting edges

- Gear wheels

- Cylindrical workpieces

- Industries

- Our products

- Werth service

- About Werth

- Careers

- Foundation

- Publications

- Downloads