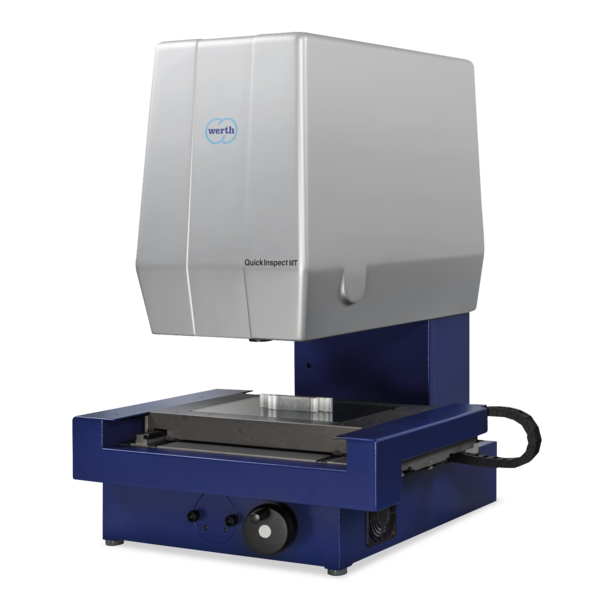

The QuickInspect enables the complete capture of the workpiece in one image and ensures extremely simple operation and short measuring times. Focusing is not necessary with most device variants due to the large depth of field of the telecentric lenses. The workpiece is placed on the measuring table of the digital measuring projector, automatically recognized and measured. With the QuickInspect MT, even small or highly accurate features on larger objects can be displayed and measured optically in the raster image with almost any resolution (patented). The area of application is 2D workpieces.

-

Applications

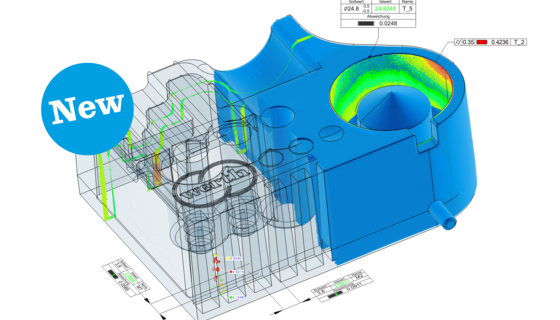

- 3D free-form workpieces

- Extruded workpieces

- Molds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Punched and bent parts

- Packaging

- Shaft-Hub Connections

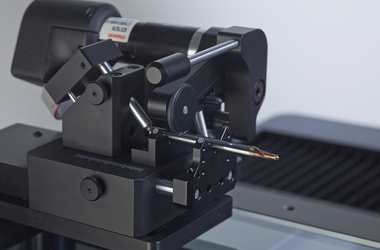

- Shafts and Axes

- Workpieces with micro-features

- Optics and Lenses

- Tools with precisely defined cutting edges

- Tools with complex or irregular cutting edges

- Gear wheels

- Cylindrical workpieces

- Industries

- Our products

- Werth service

- About Werth

- Careers

- Foundation

- Publications

- Downloads