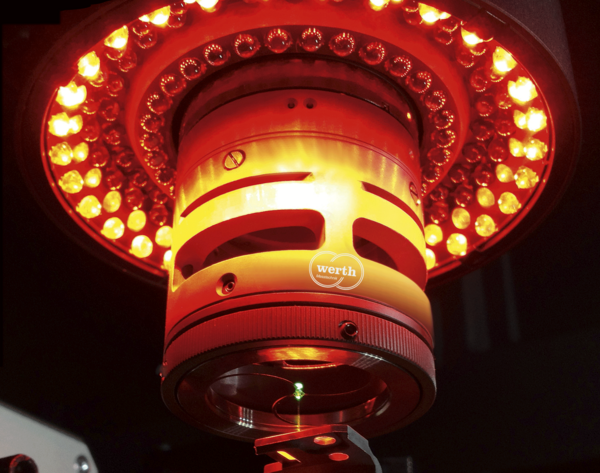

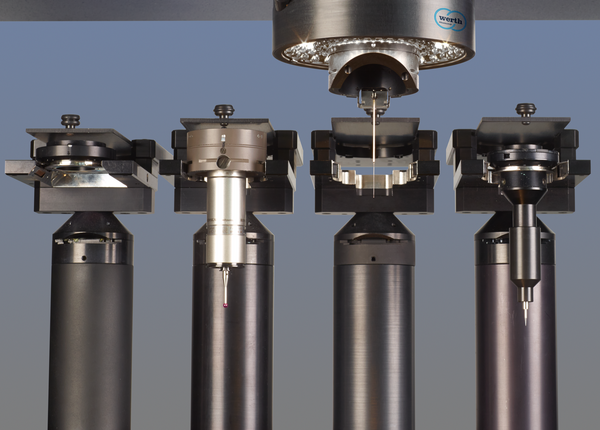

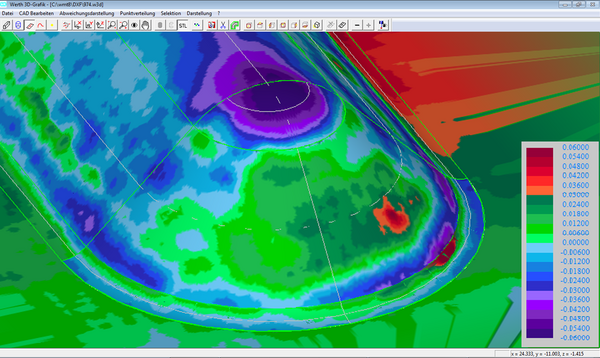

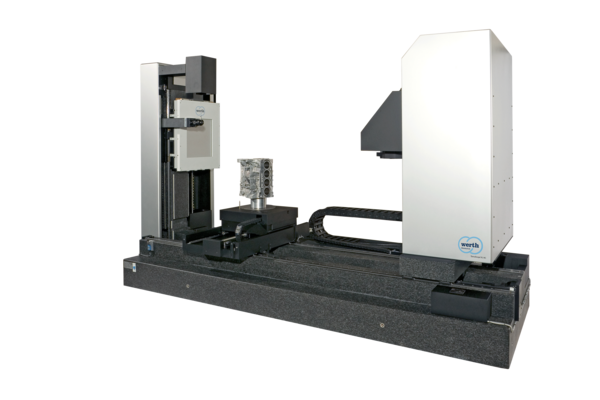

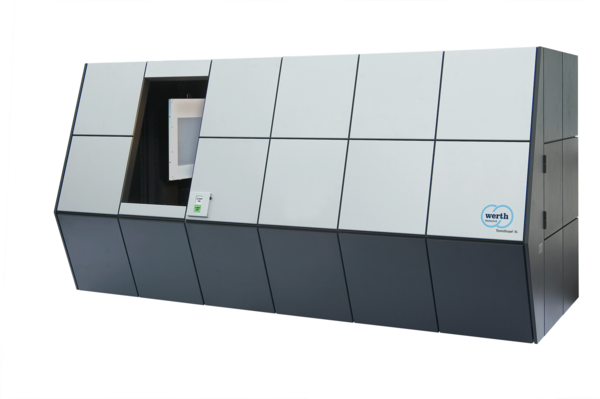

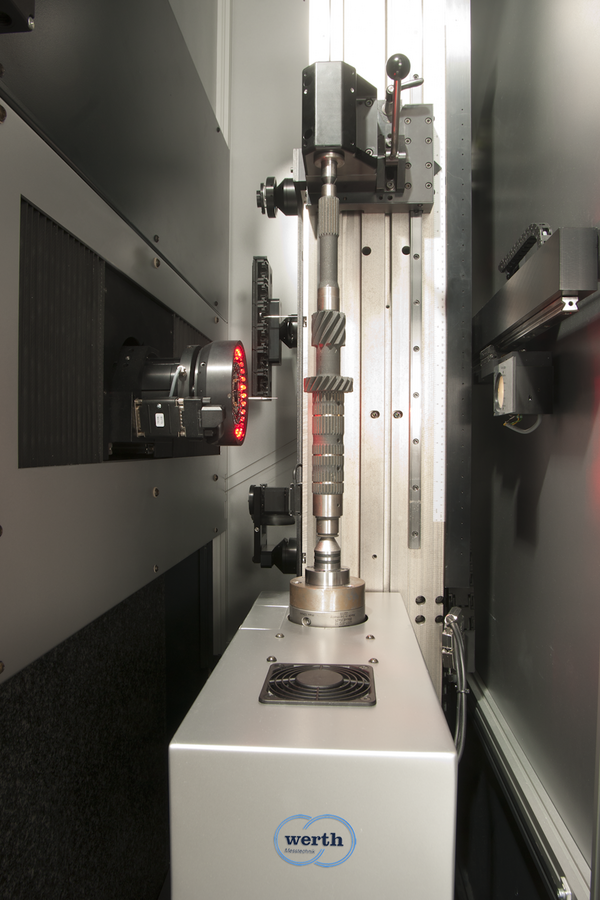

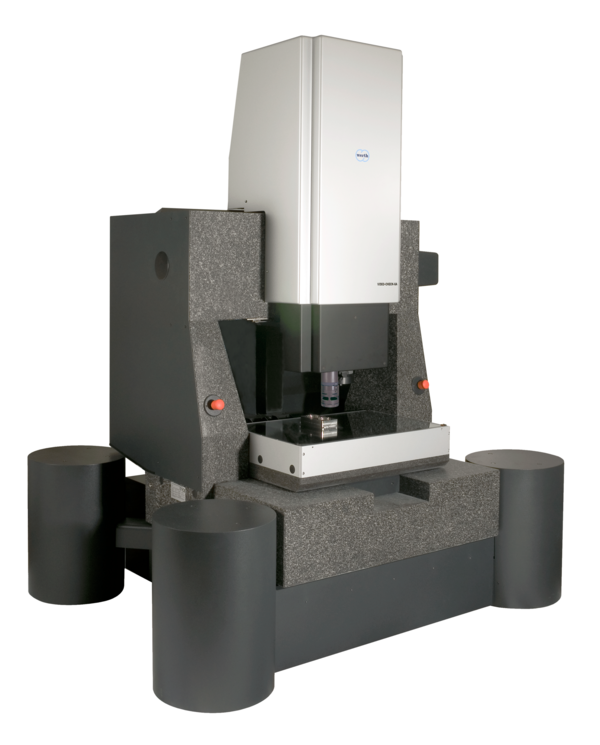

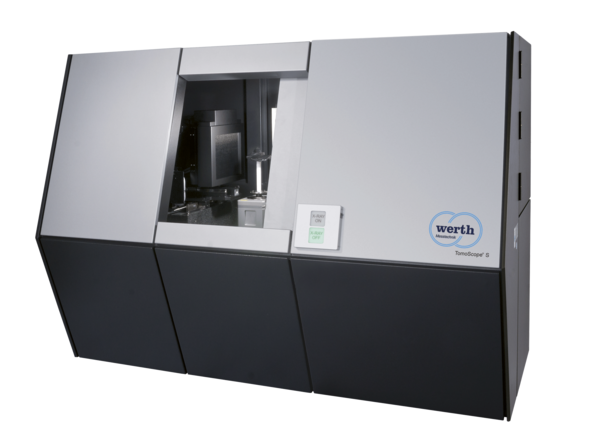

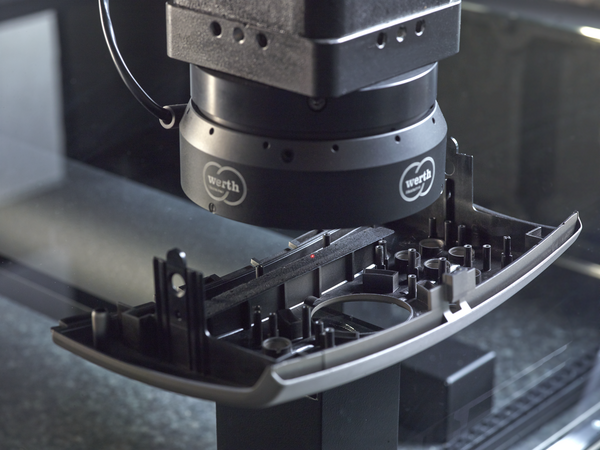

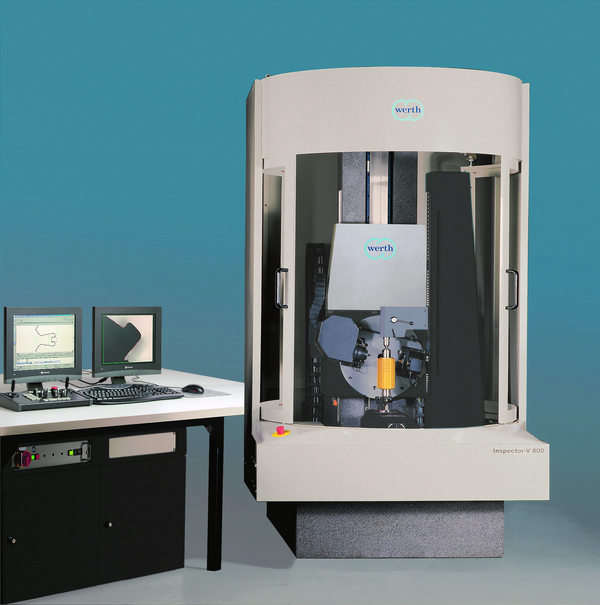

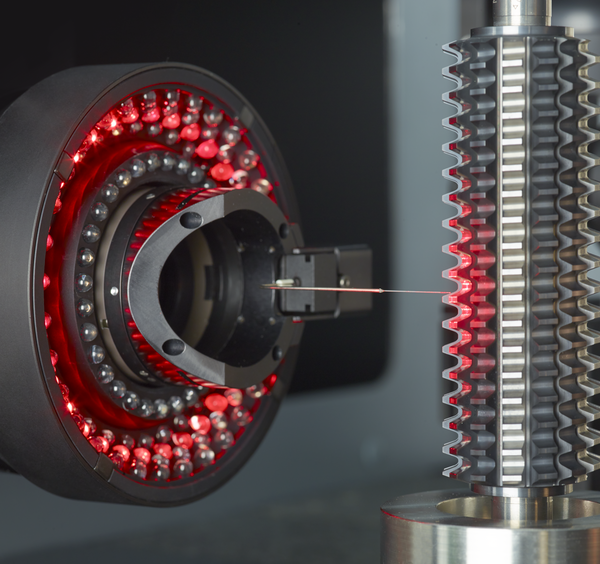

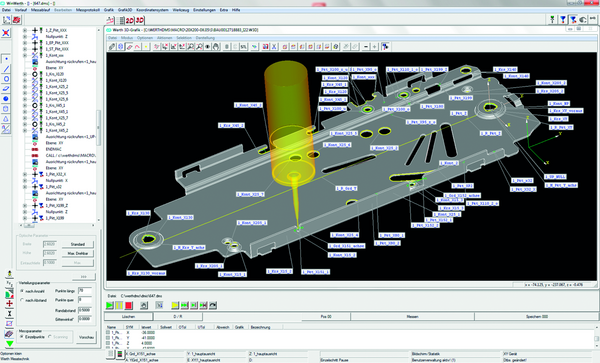

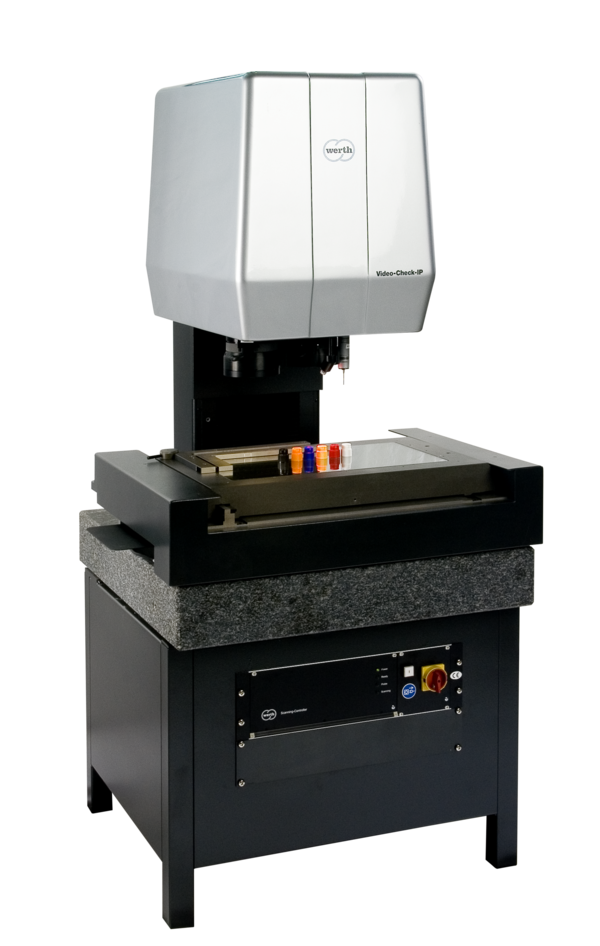

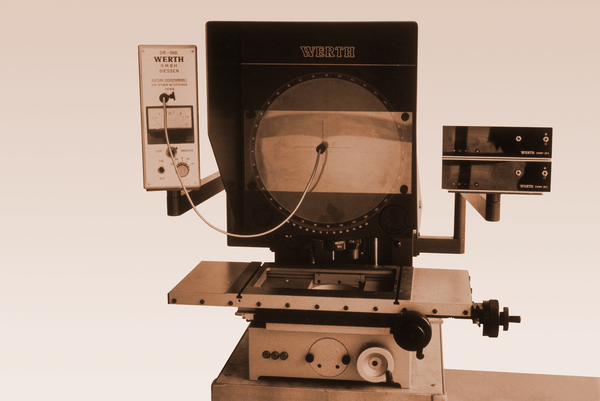

Werth, a global company with a highly motivated team with over 400 employees manufactures highly accurate coordinate measuring machines with optics, probe, computed tomography and multi-sensor systems from our global headquarter located in Giessen, Germany a region with a long tradition in the precision mechanical-optical industry.

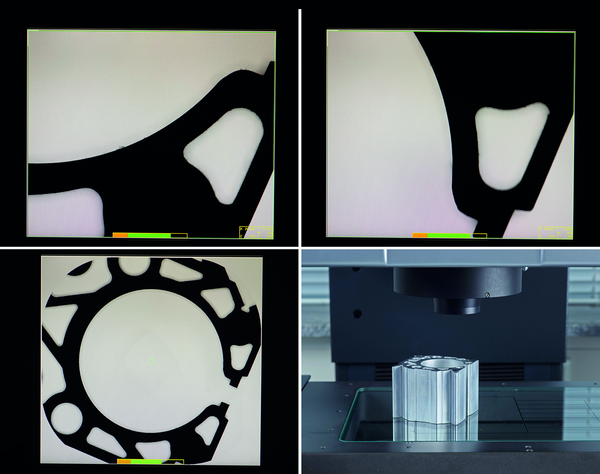

Werth, Inc., the US subsidiary of Werth Messtechnik, is situated in the picturesque town of Old Saybrook, CT. This dynamic company, established in 2003, boasts a rich history and a strong commitment to excellence. Quickly rising as a prominent player in the US metrology industry, Werth Inc offers MultiSensor & CT/X-ray equipment renowned for its unparalleled speed and precision.

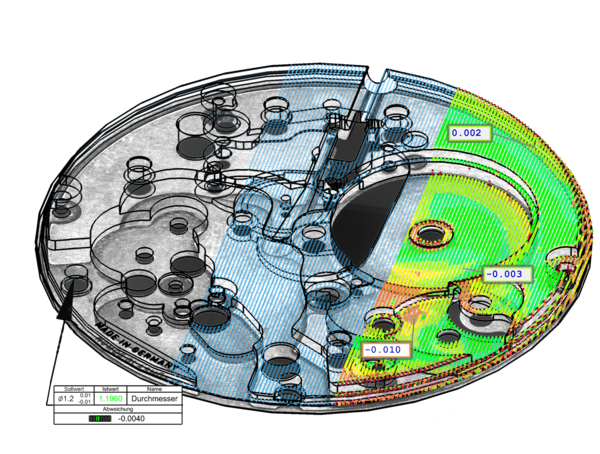

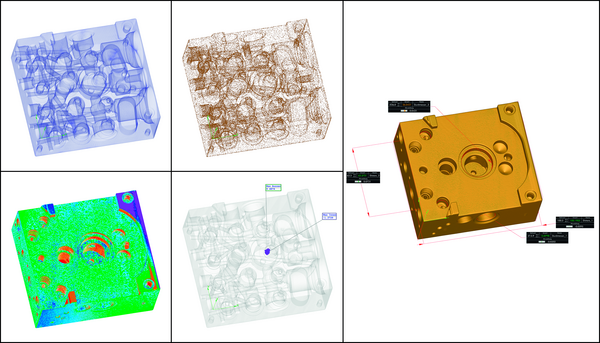

Conveniently located close to major airports in New York and Boston, and supported by service engineers strategically stationed throughout the lower 48 States, Werth, Inc. has not only made significant contributions to the local business landscape but has also played an integral role in multiple manufacturing industries, such as aerospace, medical device, automotive, plastics and electronics. The company's dedication to excellence is reflected in its rapid, and impressive growth.