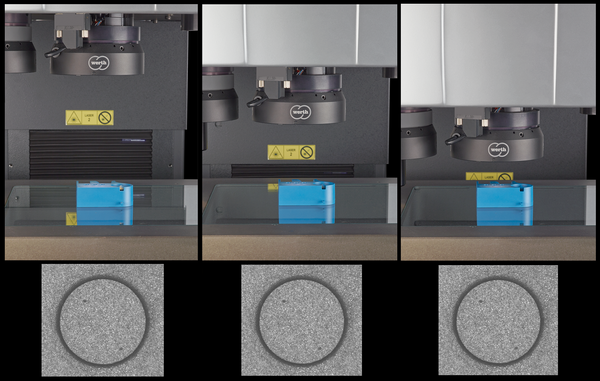

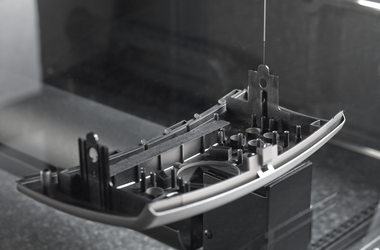

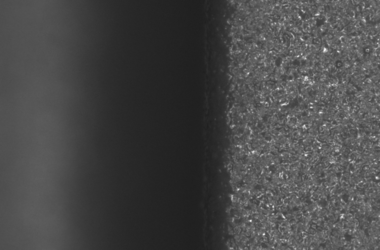

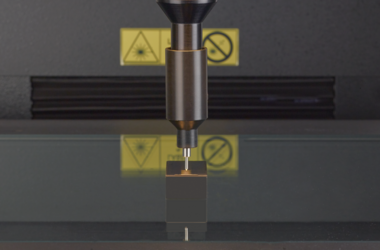

In addition to the magnification, the Werth Zoom also makes it possible to adapt the working distance between the lenses and the measuring object to the task in a "CNC-capable" manner. One benefit of the very large working distance is, for example, the ability to test blind bores with a large depth and turned parts with a large diameter without collision. Other benefits of the flexible working distance are achieved in combination with the Werth MultiRing® for changing the lighting angle. This allows object edges to be visualized that would not be visible at all with conventional lighting methods.

-

Applications

- 3D free-form workpieces

- Extruded workpieces

- Molds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Punched and bent parts

- Packaging

- Shaft-Hub Connections

- Shafts and Axes

- Workpieces with micro-features

- Optics and Lenses

- Tools with precisely defined cutting edges

- Tools with complex or irregular cutting edges

- Gear wheels

- Cylindrical workpieces

- Industries

- Our products

- Werth service

- About Werth

- Careers

- Foundation

- Publications

- Downloads