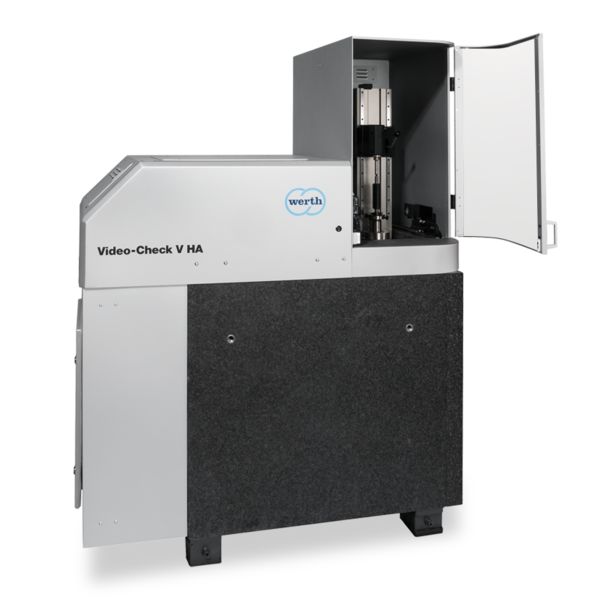

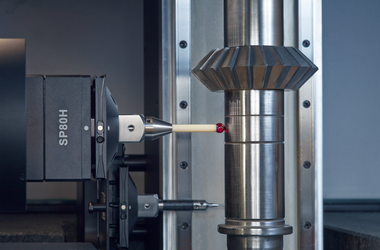

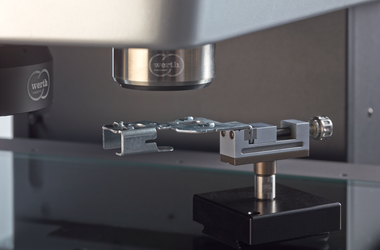

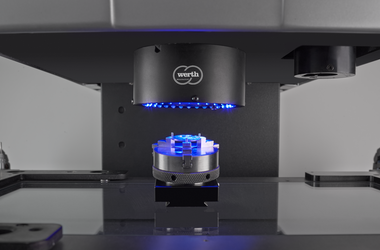

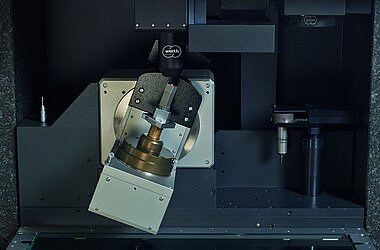

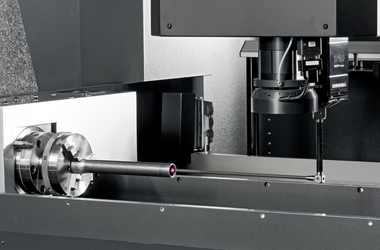

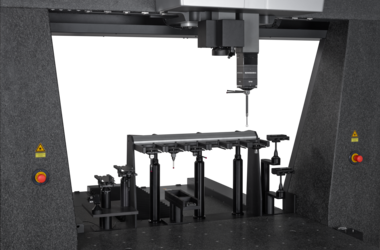

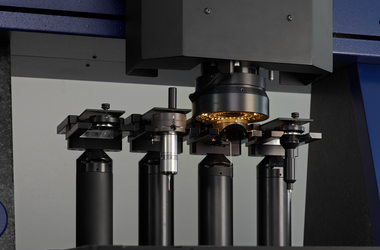

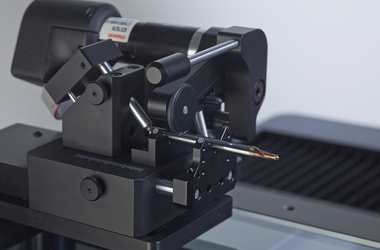

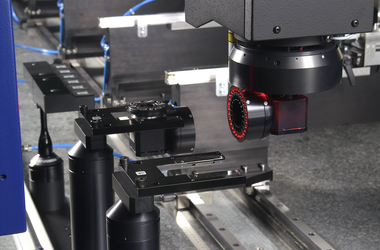

Thanks to its solid granite construction, special air bearing technology and temperature-stable scale systems, the VideoCheck® V HA achieves measurement uncertainties in the tenth of a micrometer range. The high-precision machine has an integrated vertical rotary axis so that deflection due to the dead weight of rotationally symmetrical workpieces such as shafts and tools is avoided. Workpieces such as form milling cutters, twist drills, step drills, taps and shafts are measured.

-

Applications

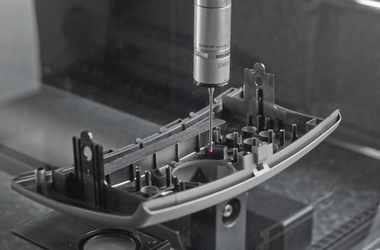

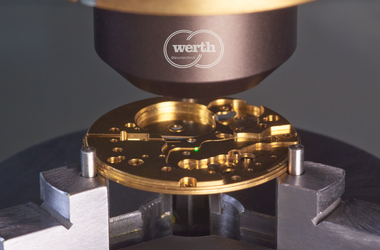

- 3D free-form workpieces

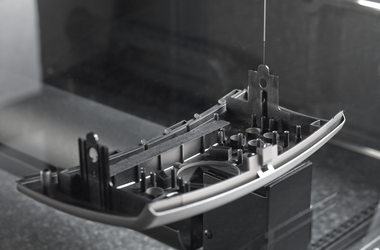

- Extruded workpieces

- Molds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Punched and bent parts

- Packaging

- Shaft-Hub Connections

- Shafts and Axes

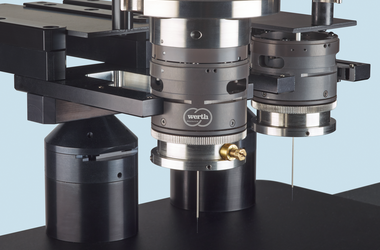

- Workpieces with micro-features

- Optics and Lenses

- Tools with precisely defined cutting edges

- Tools with complex or irregular cutting edges

- Gear wheels

- Cylindrical workpieces

- Industries

- Our products

- Werth service

- About Werth

- Careers

- Foundation

- Publications

- Downloads