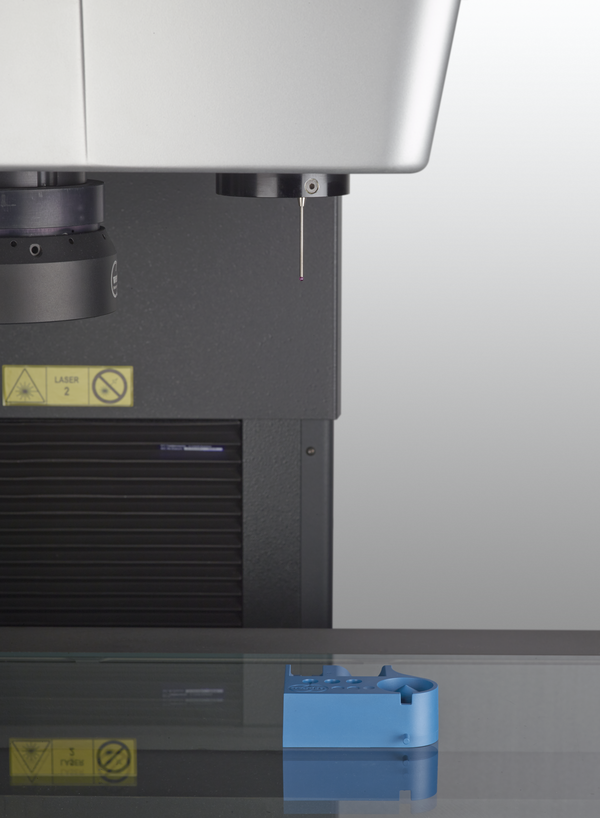

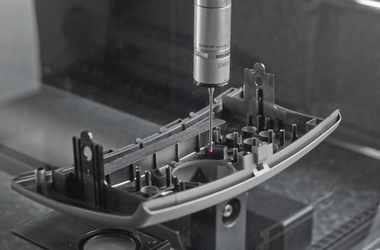

The probe retraction axis (patented) ensures ergonomics and safety during multi-sensor systems measurements. When the probe is activated, the axis positions the sensor in the measuring range. As soon as the probe is deactivated, it is returned to the park position. This enables very fast sensor changes. In addition, collisions during the measuring process are prevented and the accessibility of the workpiece for the respective sensor is improved.

-

Applications

- 3D free-form workpieces

- Extruded workpieces

- Molds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Punched and bent parts

- Packaging

- Shaft-Hub Connections

- Shafts and Axes

- Workpieces with micro-features

- Optics and Lenses

- Tools with precisely defined cutting edges

- Tools with complex or irregular cutting edges

- Gear wheels

- Cylindrical workpieces

- Industries

- Our products

- Werth service

- About Werth

- Careers

- Foundation

- Publications

- Downloads