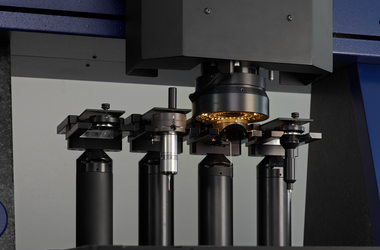

Gear wheels have a standardized geometry. They are measured according to DIN 3962.

Plastic gears in particular can have very small modules (approx. 0.03). Profile form deviation, flank line deviation and pitch are measured. Depending on the application of the gears, the tolerances range from a few µm to approx. 0.1 mm. While measurement time is considered, it is of secondary importance. In contrast to metal gears, all teeth of plastic gears must be tested, as the teeth are not interdependent due to the process.

-

Applications

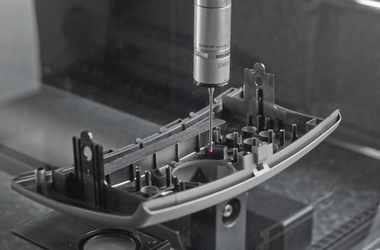

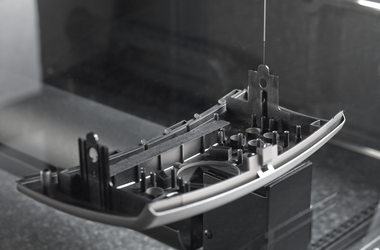

- 3D free-form workpieces

- Extruded workpieces

- Molds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Punched and bent parts

- Packaging

- Shaft-Hub Connections

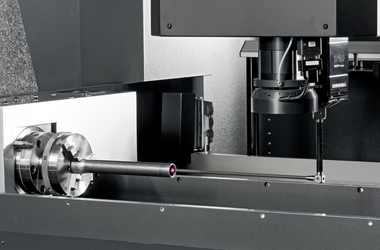

- Shafts and Axes

- Workpieces with micro-features

- Optics and Lenses

- Tools with precisely defined cutting edges

- Tools with complex or irregular cutting edges

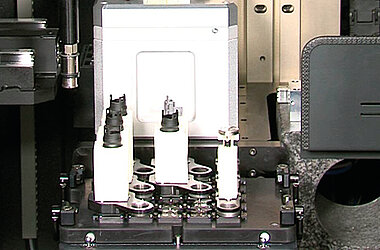

- Gear wheels

- Cylindrical workpieces

- Industries

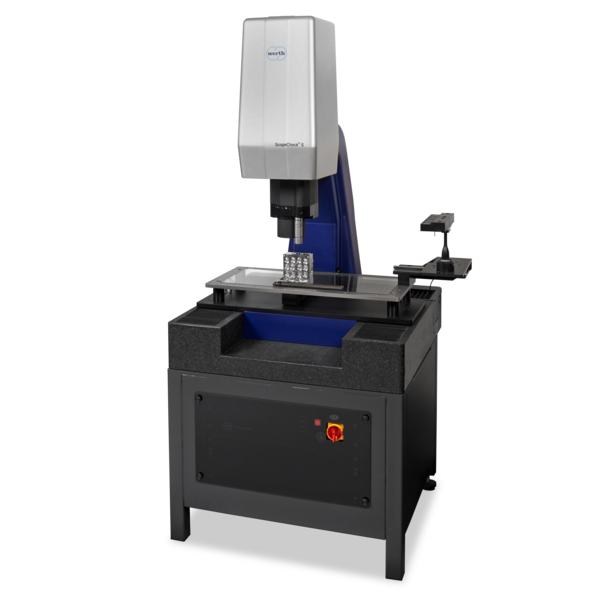

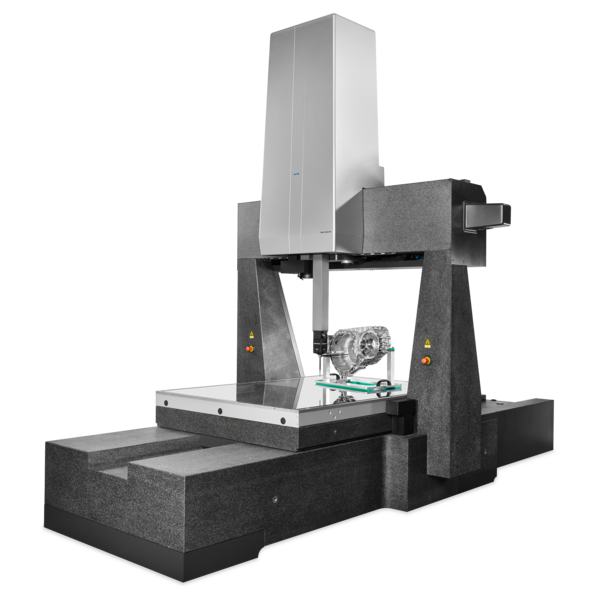

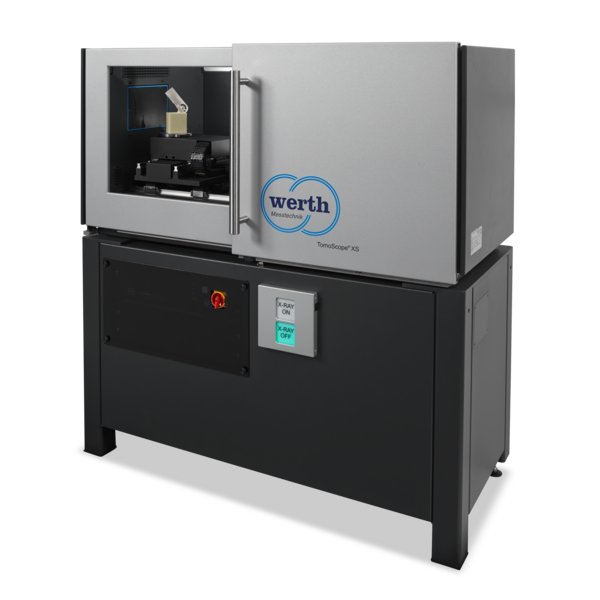

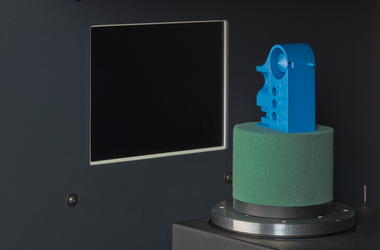

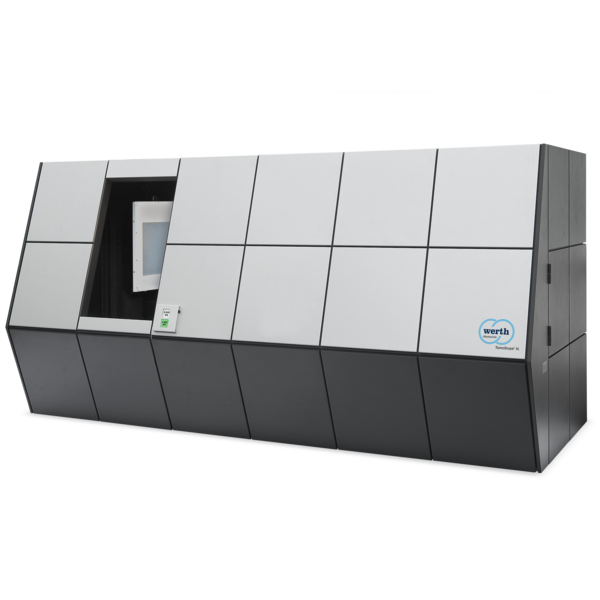

- Our products

- Werth service

- About Werth

- Careers

- Foundation

- Publications

- Downloads