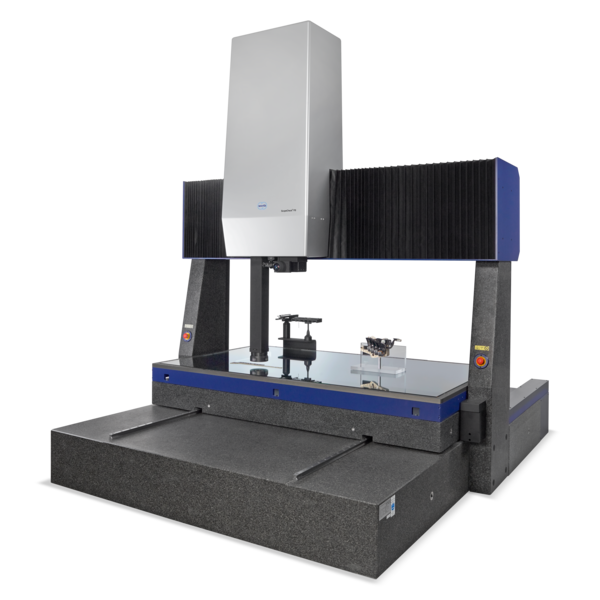

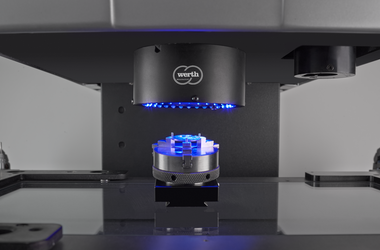

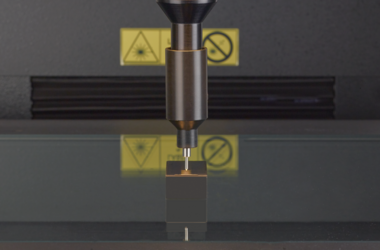

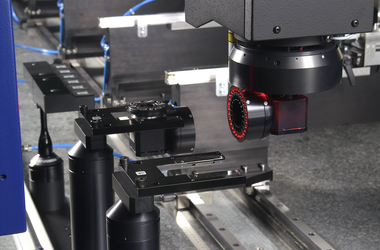

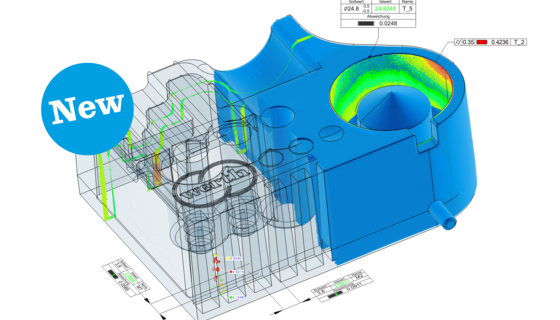

The device series perfectly combines the benefits of conventional tactile and optical coordinate measuring machines. The granite-base design with fixed bridge enables excellent specifications with maximum measuring dynamics. The ScopeCheck® FB offers the optimum combination of precision and measuring range and has compact installation dimensions and a low weight.

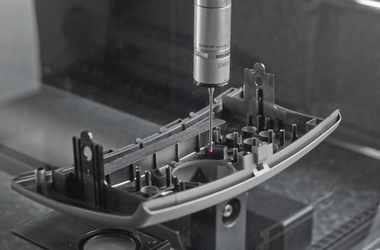

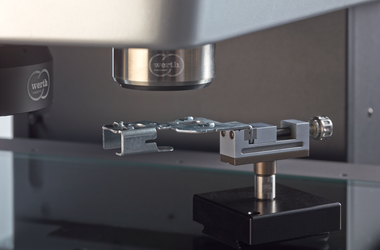

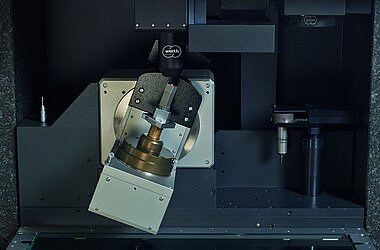

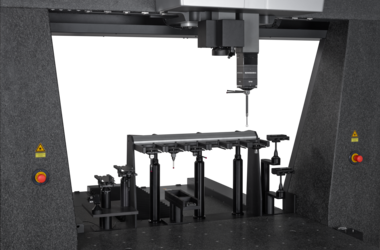

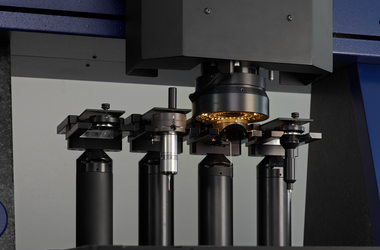

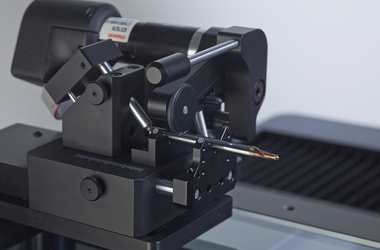

With the proven multi-ram concept, multi-sensor measurements are possible without restriction. Up to three independent sensor axes (rams) allow quick sensor changes and minimize the risk of collision.

-

Applications

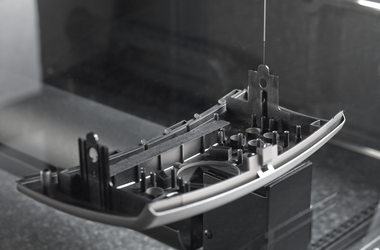

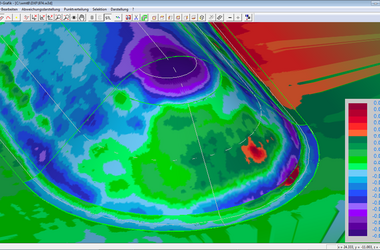

- 3D free-form workpieces

- Extruded workpieces

- Molds

- Semiconductor workpieces

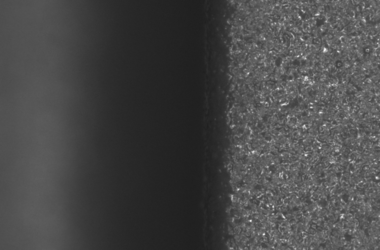

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Punched and bent parts

- Packaging

- Shaft-Hub Connections

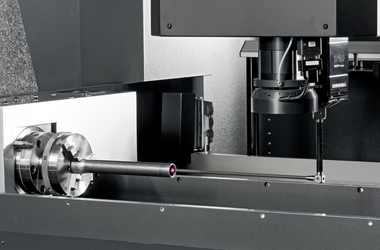

- Shafts and Axes

- Workpieces with micro-features

- Optics and Lenses

- Tools with precisely defined cutting edges

- Tools with complex or irregular cutting edges

- Gear wheels

- Cylindrical workpieces

- Industries

- Our products

- Werth service

- About Werth

- Careers

- Foundation

- Publications

- Downloads