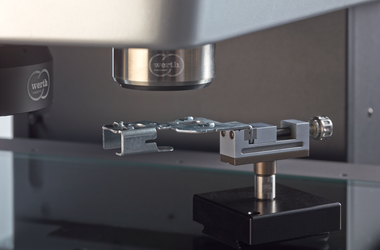

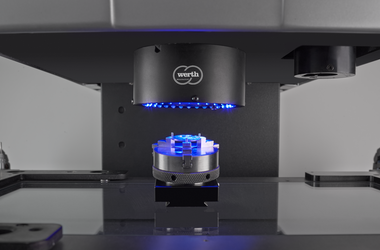

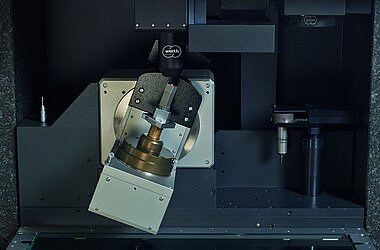

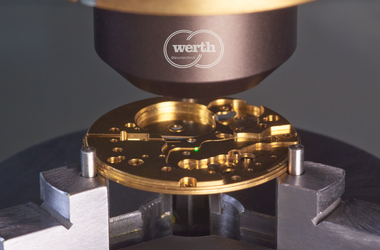

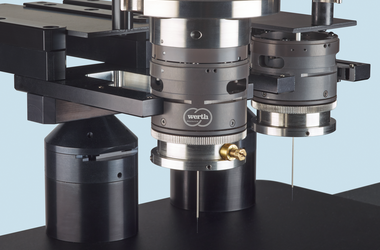

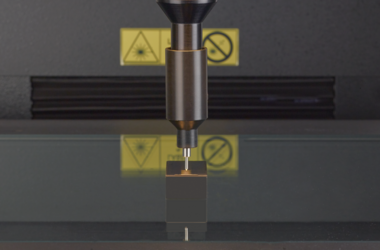

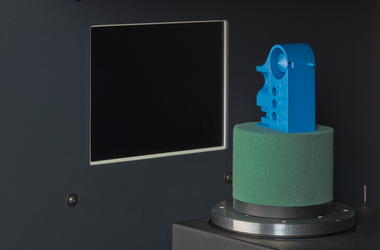

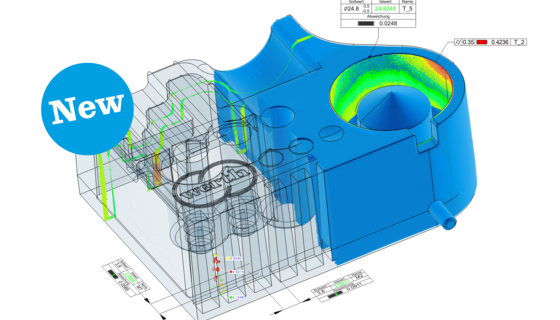

Geometric elements with different orientations, such as surfaces or bores, can be measured in the optimum alignment with multi-sensor systems. Even large sensors have access to all workpiece areas so that the entire workpiece can be measured without reclamping and the associated loss of time and accuracy. Rotary/tilt axes are available in three different variants: air bearing for maximum accuracy, with mechanical bearings for production and as a compact variant, e.g. for ScopeCheck® S, VideoCheck® S and VideoCheck® MZ.

-

Applications

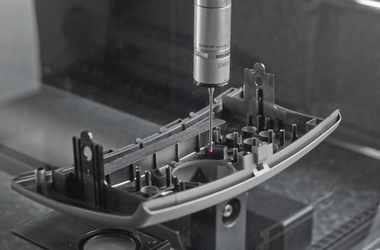

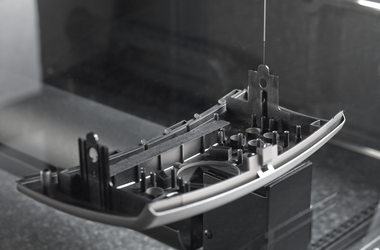

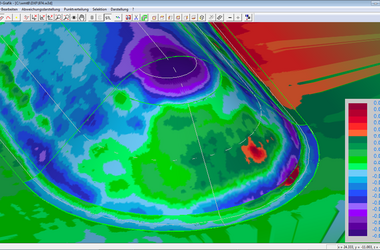

- 3D free-form workpieces

- Extruded workpieces

- Molds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Punched and bent parts

- Packaging

- Shaft-Hub Connections

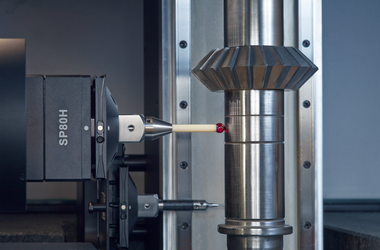

- Shafts and Axes

- Workpieces with micro-features

- Optics and Lenses

- Tools with precisely defined cutting edges

- Tools with complex or irregular cutting edges

- Gear wheels

- Cylindrical workpieces

- Industries

- Our products

- Werth service

- About Werth

- Careers

- Foundation

- Publications

- Downloads