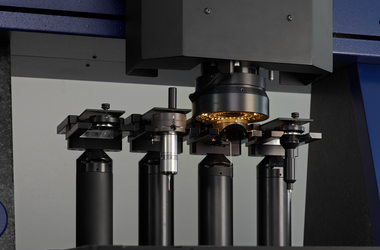

The worm grinding wheels, which can be sizable and weigh up to 60 kg, feature intricate cutting edges and a polycrystalline surface. In addition to assessing profile and pitch, angles, radii, and distances are directly measured on the worm grinding wheels or on grinding coupons. Other critical parameters include grain size, grain protrusion, and the contact ratio of the grinding surface. Tight tolerances of approximately 20 µm impose stringent requirements on measurement uncertainty. While measurement time is considered, it is of secondary importance. Moreover, during measurement, special attention must be paid to the highly reflective and sometimes transparent surface.

-

Applications

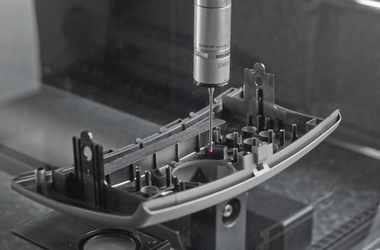

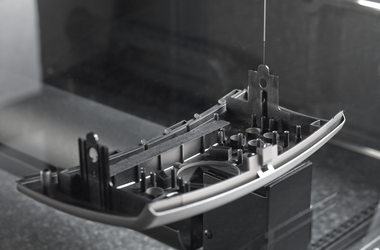

- 3D free-form workpieces

- Extruded workpieces

- Molds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Punched and bent parts

- Packaging

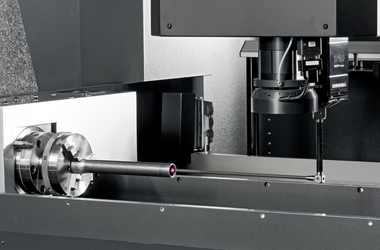

- Shaft-Hub Connections

- Shafts and Axes

- Workpieces with micro-features

- Optics and Lenses

- Tools with precisely defined cutting edges

- Tools with complex or irregular cutting edges

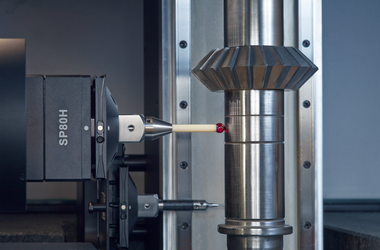

- Gear wheels

- Cylindrical workpieces

- Industries

- Our products

- Werth service

- About Werth

- Careers

- Foundation

- Publications

- Downloads