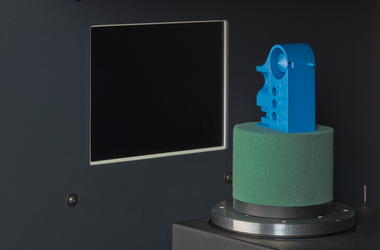

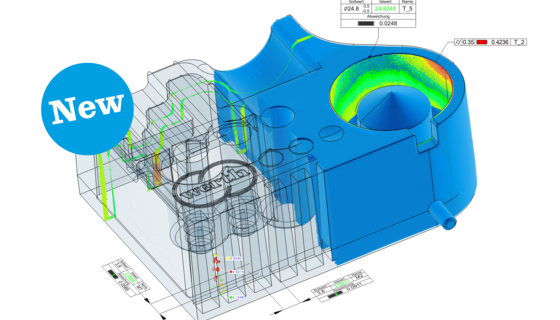

The TomoScope® XS Plus enables the measurement of larger workpieces and small objects with high resolution or reduced measurement time. Complete workpiece volumes with almost any adjustable resolution in all coordinate axes (up to 60 billion voxels) are available as measurement results. Areas of application include 3D measurements of e.g. connectors, plastic housings and covers, 3D printed workpieces, packaging, PET bottles and preforms.

-

Applications

- 3D free-form workpieces

- Extruded workpieces

- Molds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Punched and bent parts

- Packaging

- Shaft-Hub Connections

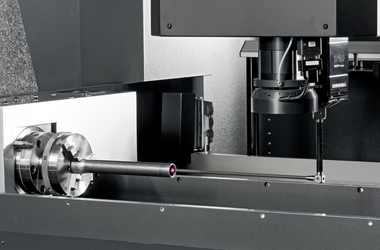

- Shafts and Axes

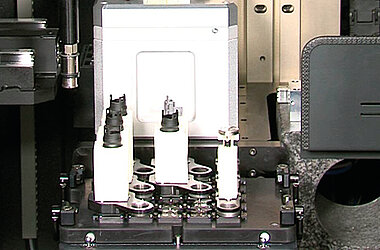

- Workpieces with micro-features

- Optics and Lenses

- Tools with precisely defined cutting edges

- Tools with complex or irregular cutting edges

- Gear wheels

- Cylindrical workpieces

- Industries

- Our products

- Werth service

- About Werth

- Careers

- Foundation

- Publications

- Downloads