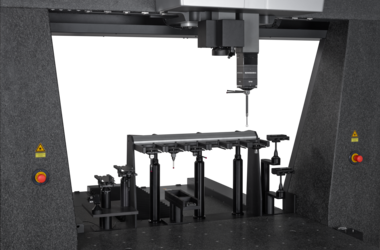

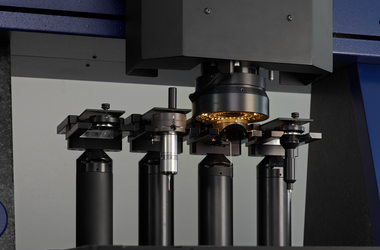

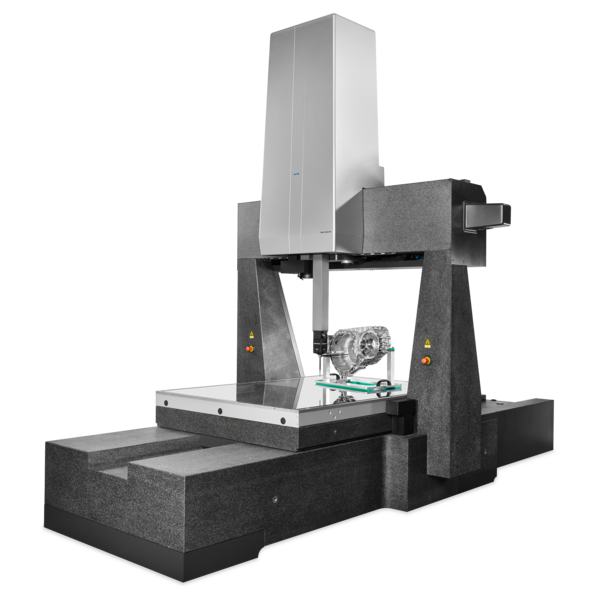

The tools are frequently adjusted iteratively until the produced workpieces meet the specified tolerances. Key geometric features include distances, radii, angles, and positional deviations. Tight tolerances ranging from 5 µm to 20 µm necessitate rigorous measurement uncertainty standards. While measurement time is considered, it is of lesser significance.

-

Applications

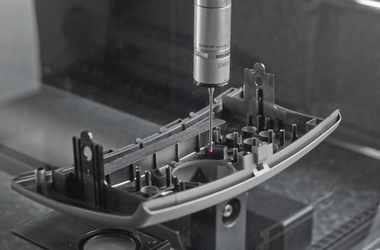

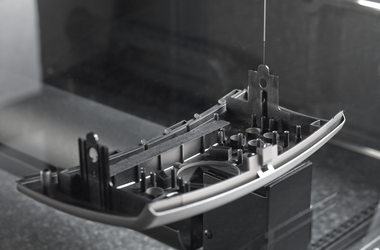

- 3D free-form workpieces

- Extruded workpieces

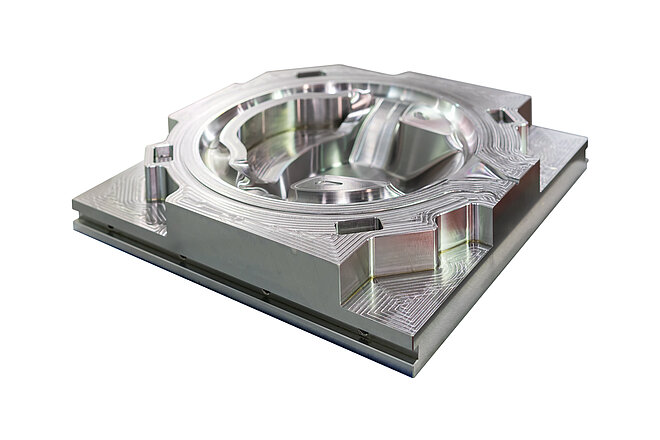

- Molds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Punched and bent parts

- Packaging

- Shaft-Hub Connections

- Shafts and Axes

- Workpieces with micro-features

- Optics and Lenses

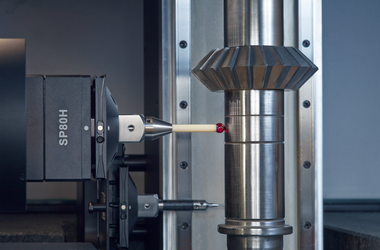

- Tools with precisely defined cutting edges

- Tools with complex or irregular cutting edges

- Gear wheels

- Cylindrical workpieces

- Industries

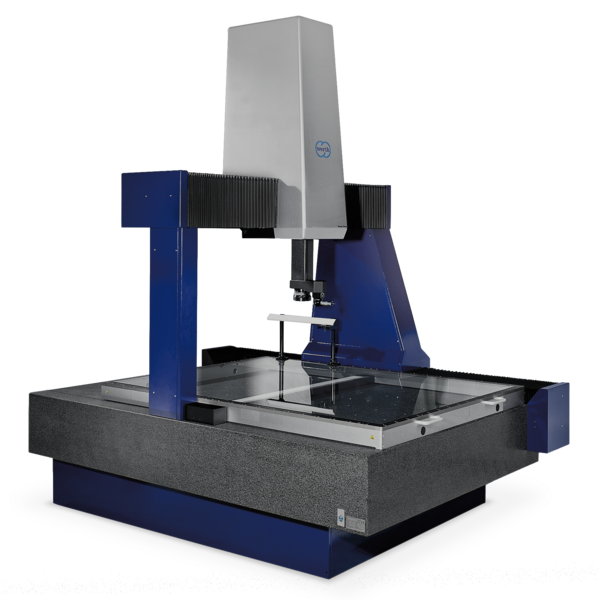

- Our products

- Werth service

- About Werth

- Careers

- Foundation

- Publications

- Downloads