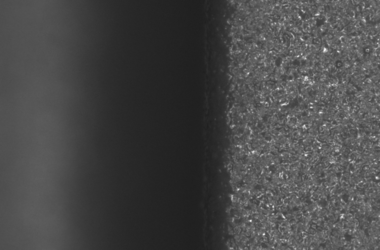

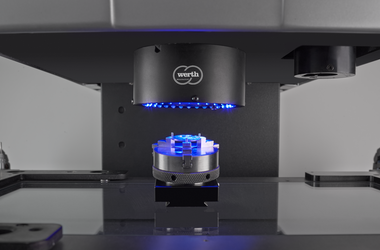

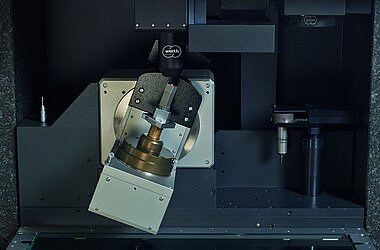

The master molds used to manufacture the molds for contact lens production must be tested. The lenses themselves must also be measured. The surface shape deviation of the lenses and tools is important. Due to the low tolerances of a few micrometers, the requirements for measurement uncertainty are very high, while the requirement for measurement time is secondary. The highly reflective tool surfaces pose a special challenge for optical measurements.

-

Applications

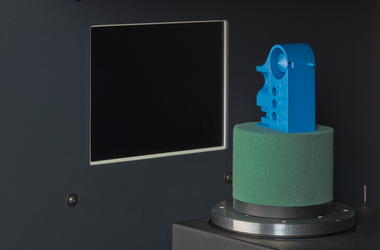

- 3D free-form workpieces

- Extruded workpieces

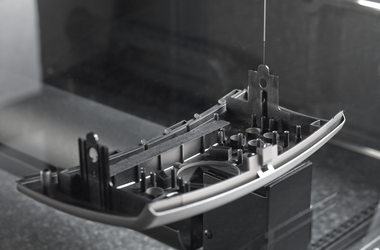

- Molds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

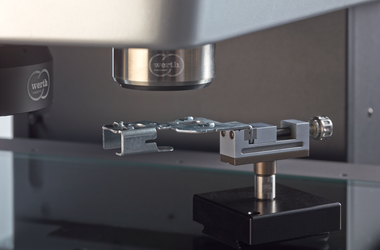

- Punched and bent parts

- Packaging

- Shaft-Hub Connections

- Shafts and Axes

- Workpieces with micro-features

- Optics and Lenses

- Tools with precisely defined cutting edges

- Tools with complex or irregular cutting edges

- Gear wheels

- Cylindrical workpieces

- Industries

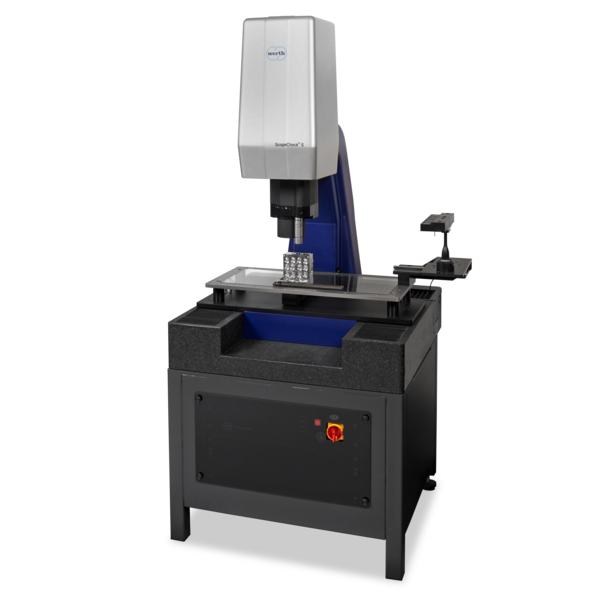

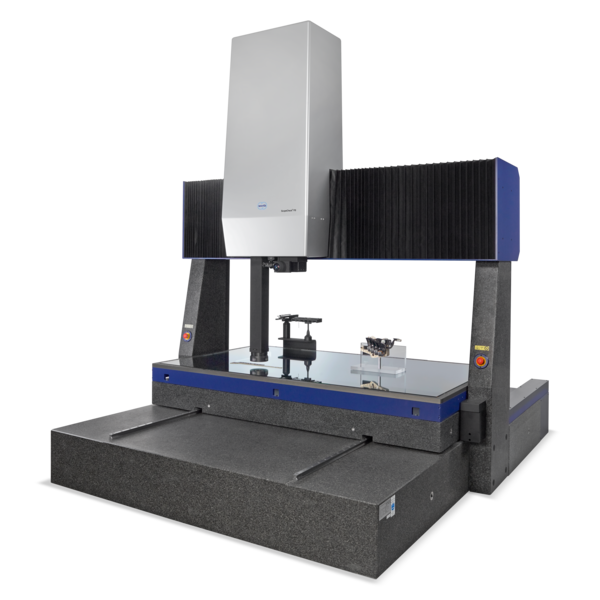

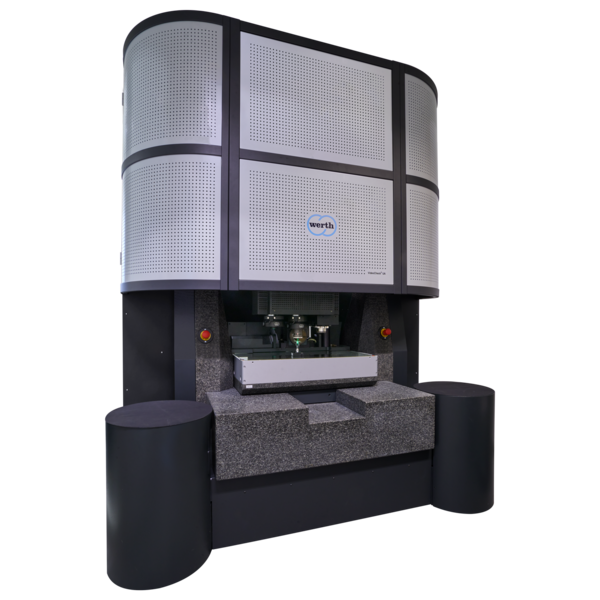

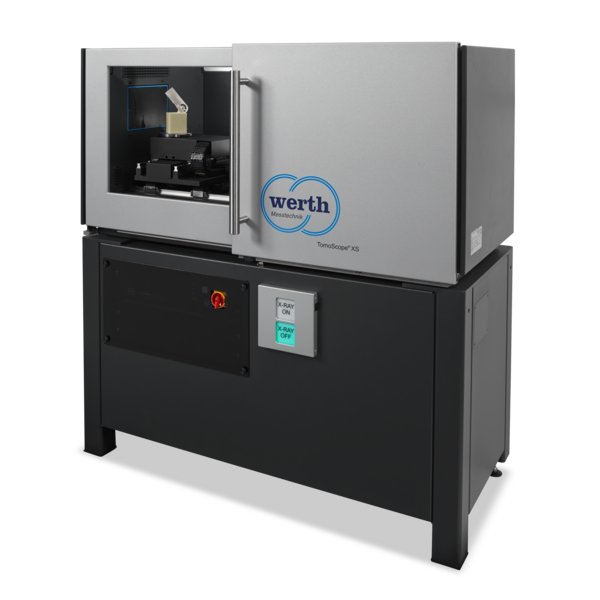

- Our products

- Werth service

- About Werth

- Careers

- Foundation

- Publications

- Downloads