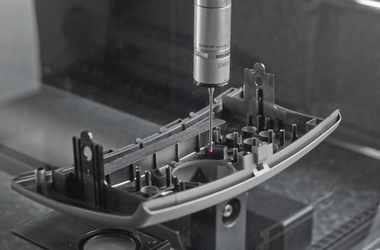

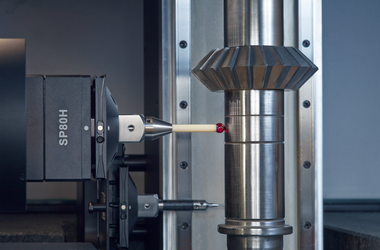

Milling cutters in indexable insert design are characterized by large diameters and a high weight. In addition to the important diameter, the profile, angles, radii and distances at the insert seat are also measured. With tolerances of approx. 10 µm to 15 µm, the requirements for measurement uncertainty are high. This also applies to the measuring speed. The use of a rotary axis is required for the measurement of milling cutters in indexable insert design.

-

Applications

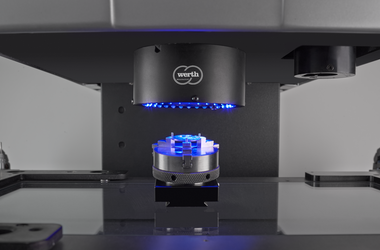

- 3D free-form workpieces

- Extruded workpieces

- Molds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Punched and bent parts

- Packaging

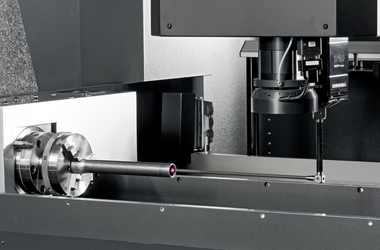

- Shaft-Hub Connections

- Shafts and Axes

- Workpieces with micro-features

- Optics and Lenses

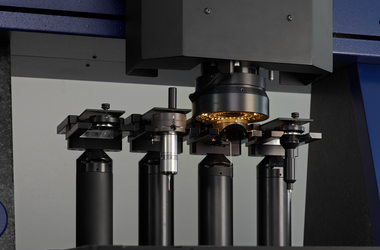

- Tools with precisely defined cutting edges

- Tools with complex or irregular cutting edges

- Gear wheels

- Cylindrical workpieces

- Industries

- Our products

- Werth service

- About Werth

- Careers

- Foundation

- Publications

- Downloads