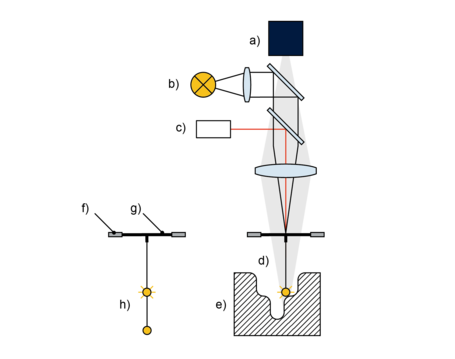

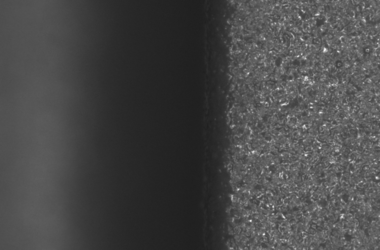

This patented tactile-optical 3D micro-probe extends the application range of the proven Werth Fiber Probe® technology to 3D measurements. It has a number of benefits over conventional micro-probes according to the mechanical-electrical principle. The WFP® is much less sensitive to breakage, offers small probe ball diameters (up to 20 micrometers) and has many times lower probing forces (less than a thousandth of a Newton). The Werth Fiber Probe® is also part of Werth's special feature in the measurement of micro-geometries.

-

Applications

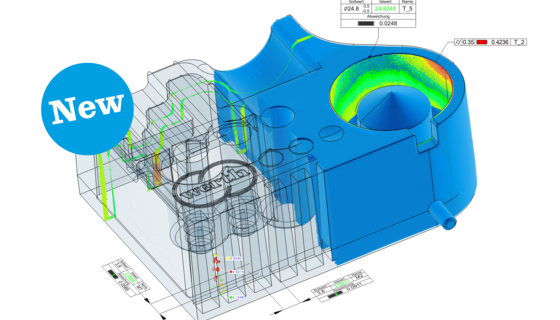

- 3D free-form workpieces

- Extruded workpieces

- Molds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Punched and bent parts

- Packaging

- Shaft-Hub Connections

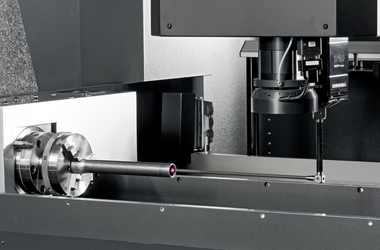

- Shafts and Axes

- Workpieces with micro-features

- Optics and Lenses

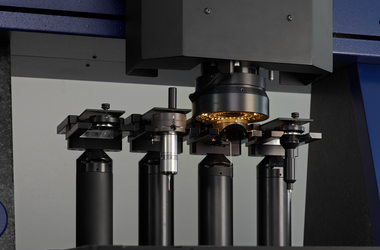

- Tools with precisely defined cutting edges

- Tools with complex or irregular cutting edges

- Gear wheels

- Cylindrical workpieces

- Industries

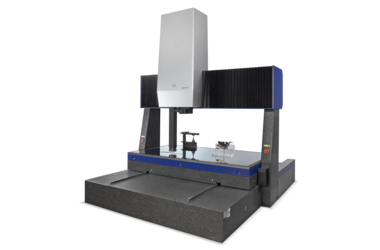

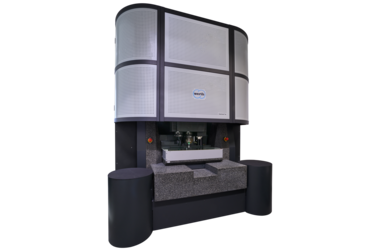

- Our products

- Werth service

- About Werth

- Careers

- Foundation

- Publications

- Downloads