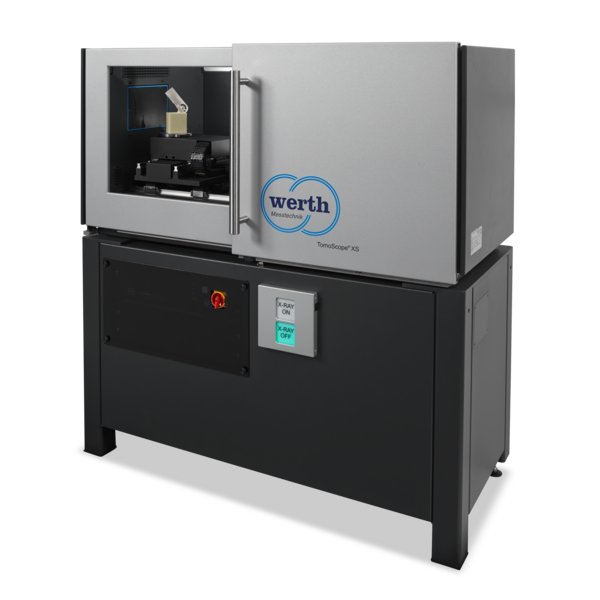

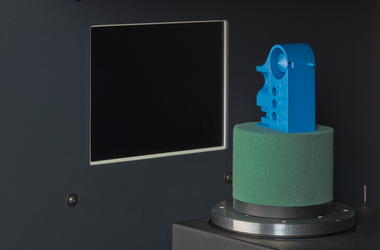

Thanks to the transmission tube – for the first time in monoblock design – a small focal spot is achieved even with high tube power, so that fast measurements with high resolution can be carried out. The monoblock design of tube, voltage generator and vacuum generation has been realized for the first time in an open design. This results in both long maintenance intervals and a theoretically unlimited service life. Areas of application include 3D measurements of connectors, plastic housings and covers, 3D printed workpieces, packaging, PET bottles and preforms. The TomoScope® XS can also be used for mold correction. The functionality and wear of the tools can be checked based on the measurements on the workpiece. For example, the workpieces are checked for signs of tool chipping and burr formation.

-

Applications

- 3D free-form workpieces

- Extruded workpieces

- Molds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Punched and bent parts

- Packaging

- Shaft-Hub Connections

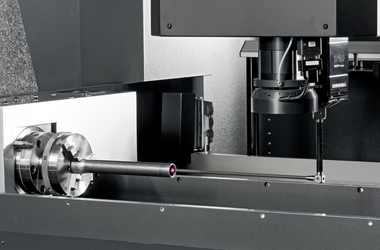

- Shafts and Axes

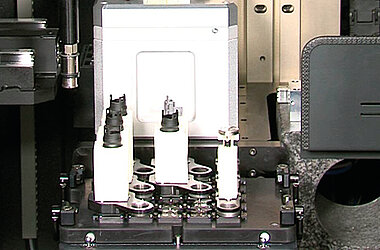

- Workpieces with micro-features

- Optics and Lenses

- Tools with precisely defined cutting edges

- Tools with complex or irregular cutting edges

- Gear wheels

- Cylindrical workpieces

- Industries

- Our products

- Werth service

- About Werth

- Careers

- Foundation

- Publications

- Downloads