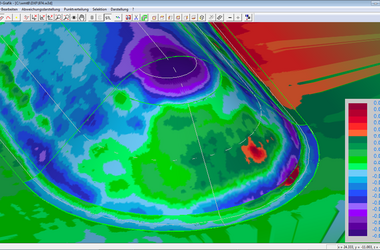

The cooling holes have different angles to the blade surface. The outlet area is shaped like a funnel. The most important geometrical characteristics are the diameter, roundness, angle and depth of the cooling holes as well as the residual wall thickness from the end of the cooling hole to the opposite blade surface. With tolerances of 50 µm to 200 µm, the requirements for measurement uncertainty are rather low. The measurement time plays a subordinate role.

-

Applications

- 3D free-form workpieces

- Extruded workpieces

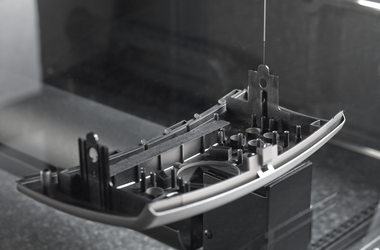

- Molds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Punched and bent parts

- Packaging

- Shaft-Hub Connections

- Shafts and Axes

- Workpieces with micro-features

- Optics and Lenses

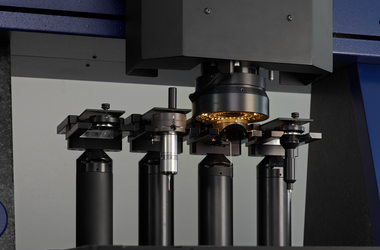

- Tools with precisely defined cutting edges

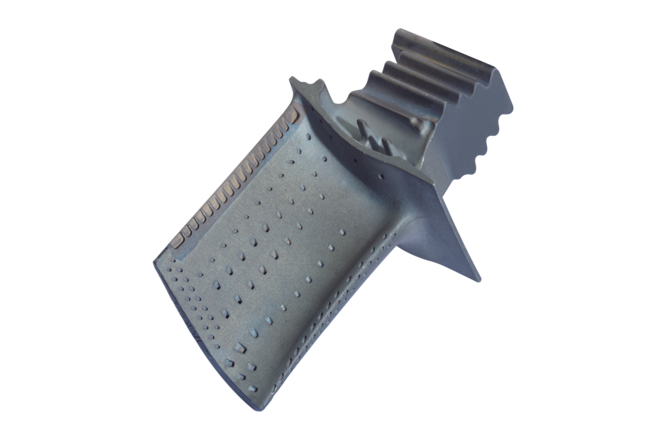

- Tools with complex or irregular cutting edges

- Gear wheels

- Cylindrical workpieces

- Industries

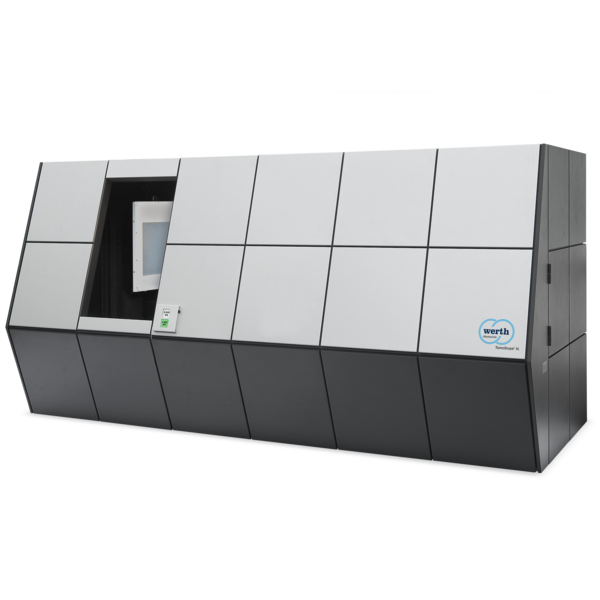

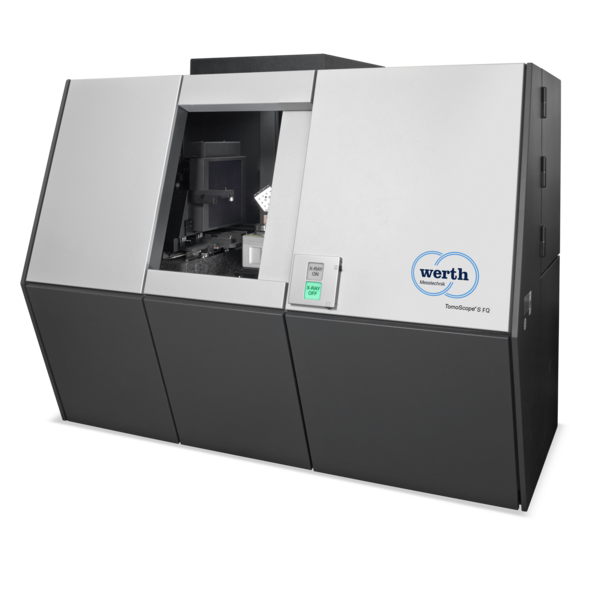

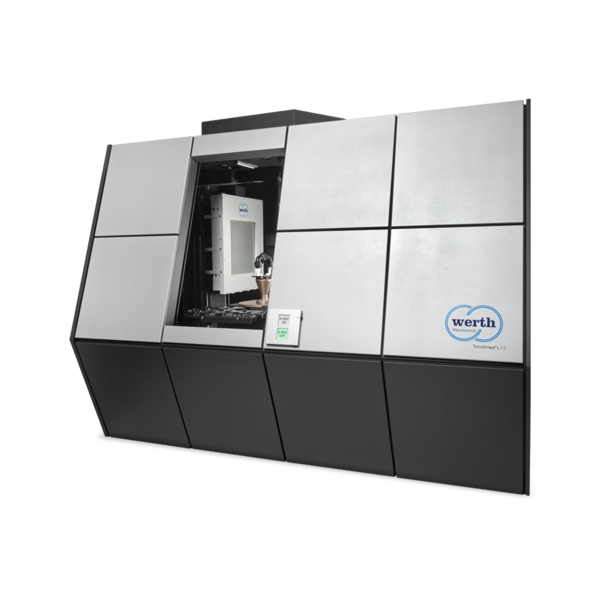

- Our products

- Werth service

- About Werth

- Careers

- Foundation

- Publications

- Downloads