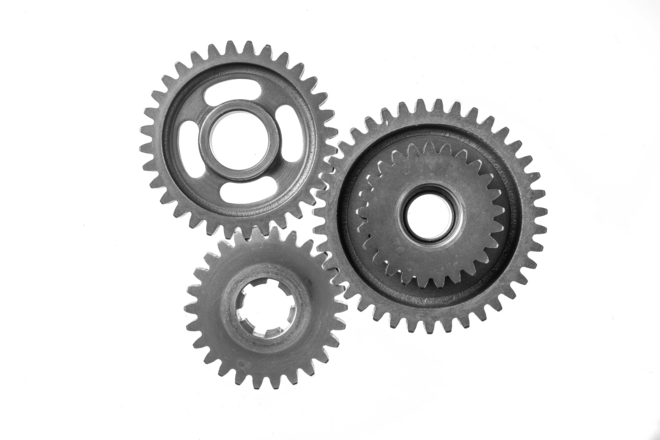

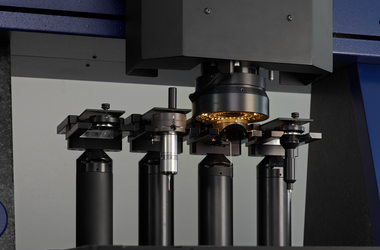

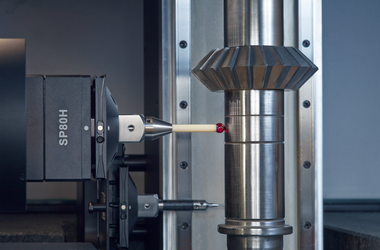

Gear wheels have a standardized geometry. Their measurement is carried out in accordance with DIN 3962, measuring profile form deviation, flank line deviation, pitch, circular run-out radial and tool thickness. Depending on the application of the gears, the tolerances range from a few µm to 100 µm. While measurement time is considered, it is of secondary importance.

-

Applications

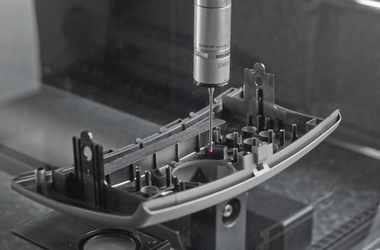

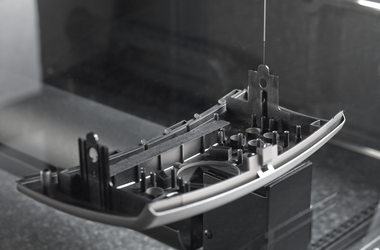

- 3D free-form workpieces

- Extruded workpieces

- Molds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

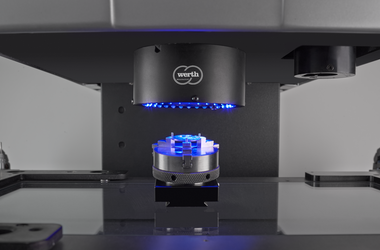

- Prismatic workpieces

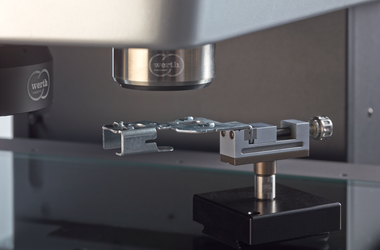

- Punched and bent parts

- Packaging

- Shaft-Hub Connections

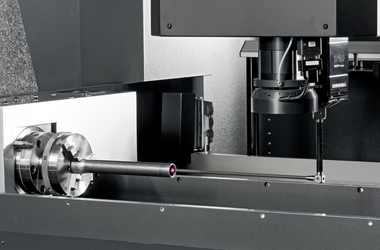

- Shafts and Axes

- Workpieces with micro-features

- Optics and Lenses

- Tools with precisely defined cutting edges

- Tools with complex or irregular cutting edges

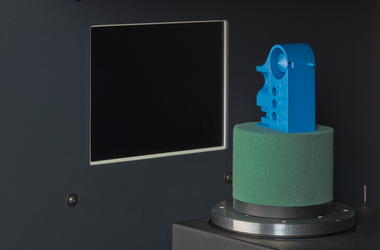

- Gear wheels

- Cylindrical workpieces

- Industries

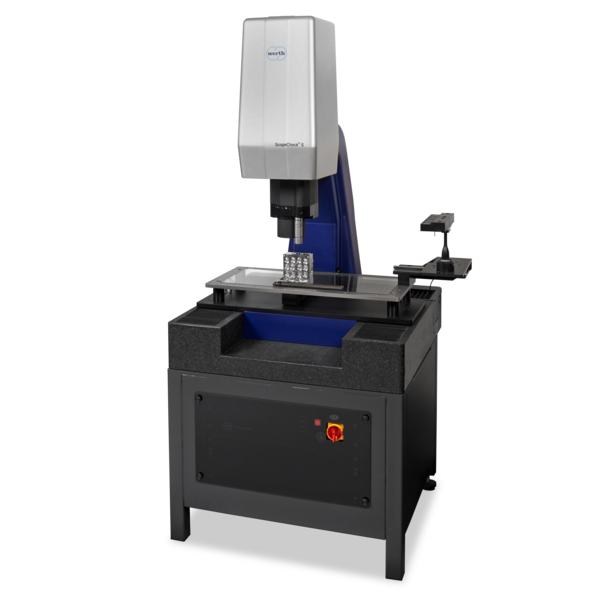

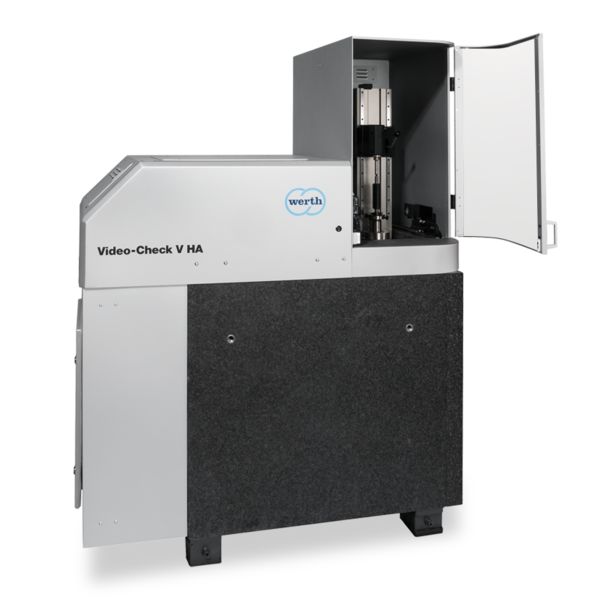

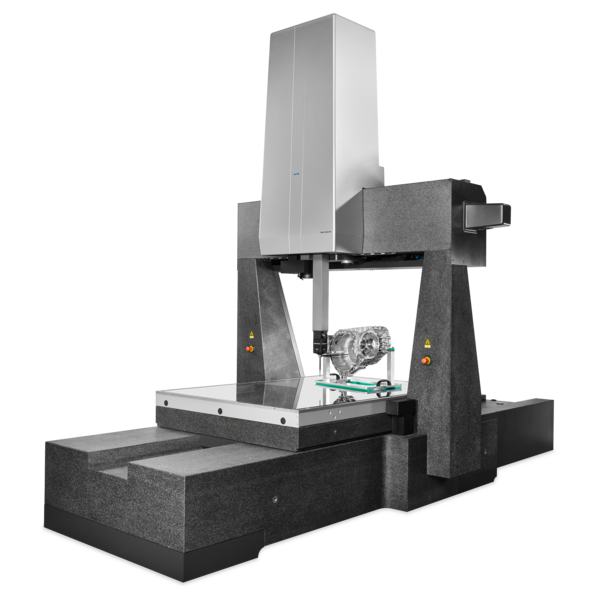

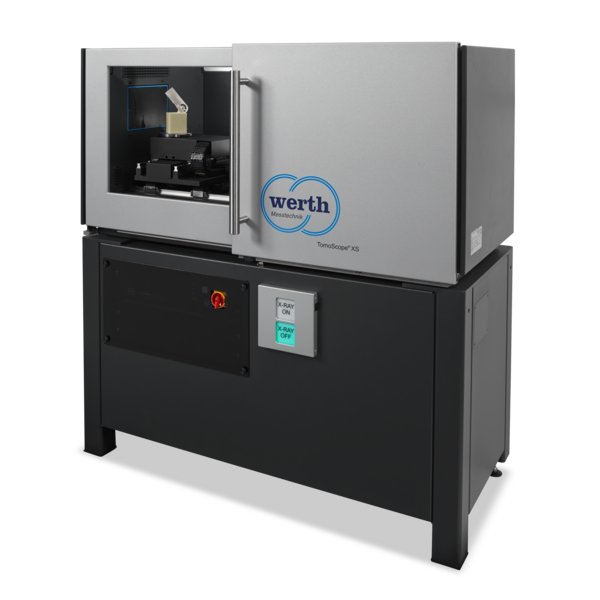

- Our products

- Werth service

- About Werth

- Careers

- Foundation

- Publications

- Downloads