Crimp contacts are often manufactured as the final processing stage by forming punched strips. In addition to geometric dimensions, crimp contacts are tested for tool marks from the bending process. With tolerances of 20 µm to 50 µm, the requirements for measurement uncertainty are in the medium range. The same applies to the measurement time.

-

Applications

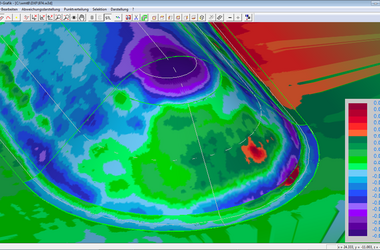

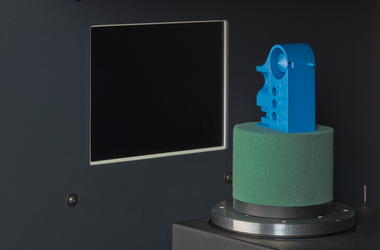

- 3D free-form workpieces

- Extruded workpieces

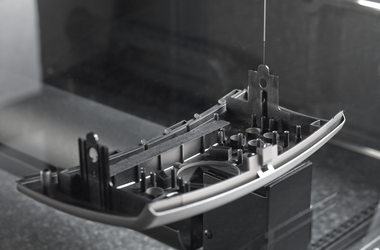

- Molds

- Semiconductor workpieces

- Lithographic structures

- Metal-plastic composite workpieces

- Prismatic workpieces

- Punched and bent parts

- Packaging

- Shaft-Hub Connections

- Shafts and Axes

- Workpieces with micro-features

- Optics and Lenses

- Tools with precisely defined cutting edges

- Tools with complex or irregular cutting edges

- Gear wheels

- Cylindrical workpieces

- Industries

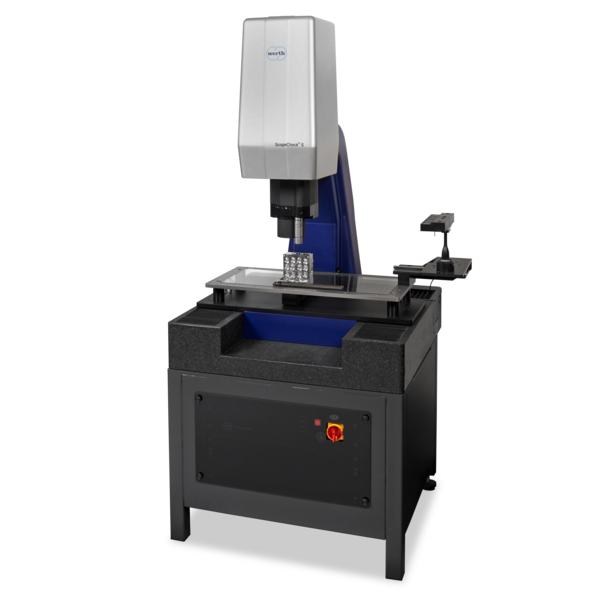

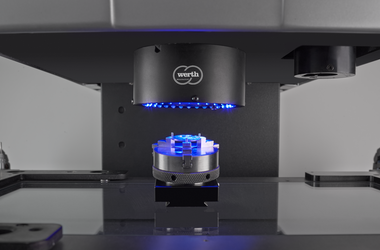

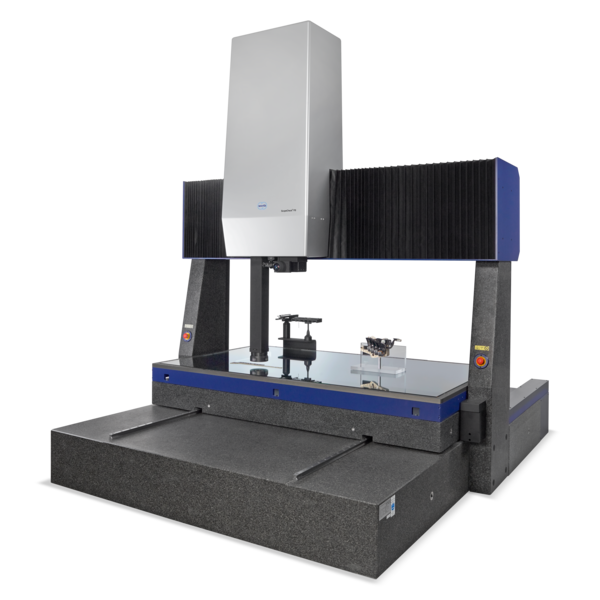

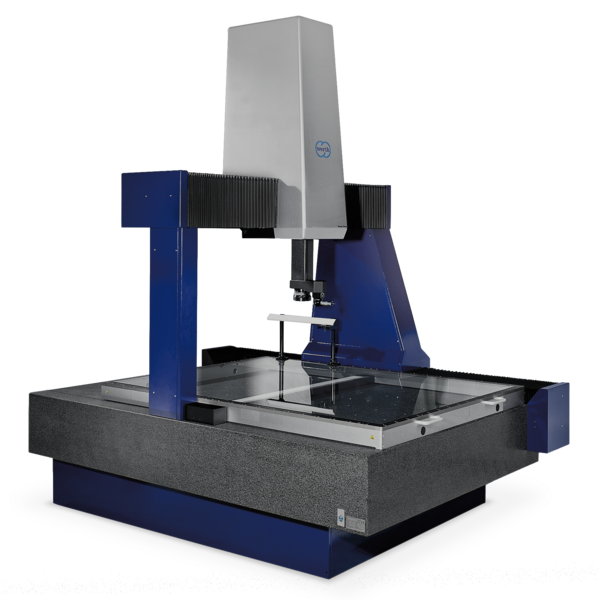

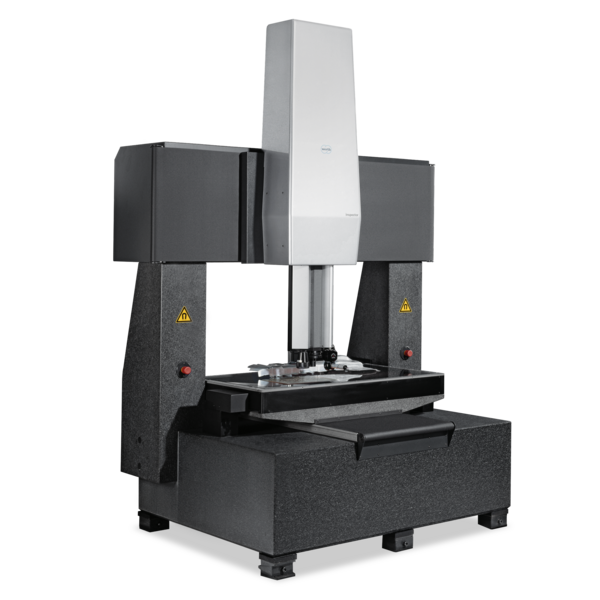

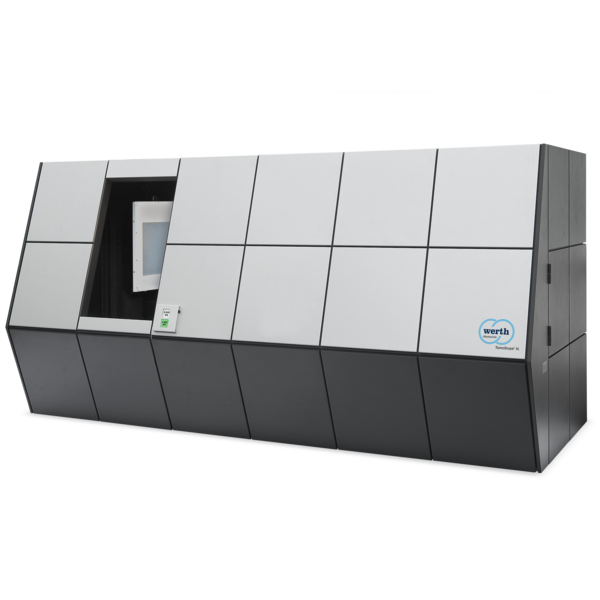

- Our products

- Werth service

- About Werth

- Careers

- Foundation

- Publications

- Downloads